Printed circuit boards (PCBs) are used in a wide variety of industries around the world, and the fabrication process can be equally diverse. Depending on numerous factors like design complexity and final application, PCB fabrication can be short or time-consuming, relatively simple or complex.

Anyone planning a project that makes use of PCBs will want to be aware of these intricacies. A deep understanding of PCB fabrication will give you the ability to plan, manage, and budget your project more efficiently.

This guide will give you:

- The basics of PCB fabrication.

- The steps of a typical PCB fabrication process from raw materials to finished boards.

- An explanation of the layers that make up PCBs.

- An idea of the factors that influence the time and resources required for PCB fabrication.

We’ll start with an overview of PCB fabrication and why it’s so important.

What is PCB Fabrication?

PCB fabrication is the process of transforming a schematic design into a physical board that can be used to support and connect electronic components. The PCB is then used as the foundation for complete electronic devices.

Almost every modern electronic device relies on a PCB. Everything from the smartphone in your pocket to modern industrial machinery is built using PCBs

What Industries Rely on PCBs?

Modern PCBs are highly versatile. This is by necessity, since they support products and processes in virtually every major industry in the world. A few examples include:

Consumer Electronics

In consumer electronics, PCBs are the core component that allows devices to function efficiently and reliably. For example, in smartphones, PCBs provide the compact yet complex circuitry needed to support high-speed data processing, wireless communication, and power management within a small form factor.

Aerospace

In aircraft avionics, PCBs are responsible for critical functions such as navigation, communication, and flight control systems. PCBs used in the aerospace industry must meet rigorous standards due to the extreme conditions they are exposed to, including high altitudes, intense vibrations, and temperature fluctuations.

Defense

The defense sector relies heavily on PCBs for a wide range of applications, from communication systems to weapons control and surveillance equipment. Like aerospace, military-grade PCBs are designed to withstand harsh environments, including exposure to moisture, dust, and electromagnetic interference.

Manufacturing

In industrial manufacturing, PCBs are essential for automating processes and ensuring operational efficiency. PCBs are used in machinery control systems, where they regulate motors, sensors, and other automated components.

Medicine

Medical devices often require PCBs that are not only highly reliable but also capable of handling sensitive data and providing precise control. For instance, in pacemakers, PCBs manage the device’s electrical impulses that regulate heartbeats, necessitating flawless performance over many years.

Industries that use PCBs typically don’t make them on their own. Instead, they rely on PCB suppliers and manufacturers further up the supply chain. There’s a few reasons for this, but the main one is that PCB manufacturing is an extremely complex process requiring both high-tech machinery and expert knowledge.

The PCB Fabrication Process

Transforming raw materials into a PCB is a delicate process. Small errors at any step can result in PCBs that don’t function properly, don’t function at all, or even boards that are dangerous to consumers.

Depending on the application intended for the PCB, different processes may be used. Here’s a general outline of the PCB fabrication process so you can get familiar with it. We’ll break down some of the more nuanced production processes later in this guide.

1. Design and Layout

The fabrication process starts with the design and layout phase. Engineers use specialized software to create a detailed schematic of the PCB. This design outlines:

- Placement of components

- Routing of electrical connections

- Overall board structure

The accuracy of this design is essential. Any errors here can lead to malfunctioning boards or require costly redesigns.

2. Material Selection

With the design finalized, the next step is choosing the right materials. These materials include:

- Substrate Material: Provides mechanical support and insulation. Commonly made from FR-4, a composite of fiberglass and epoxy resin.

- Conductive Layers: Typically copper, chosen for its excellent electrical conductivity. These layers form the pathways that connect components.

The choice of materials directly impacts the board’s performance and suitability for its intended application.

3. Layering and Lamination

The board starts to take shape during the layering and lamination process. This involves:

- Laminating multiple layers of copper and insulating materials together

- Applying high pressure and temperature to form the board’s structure

This process is especially important for multilayer PCBs, which require complex interconnections across several layers. We go into much more depth on layering in the following section.

4. Etching and Drilling

Once the layers are in place, the board undergoes etching and drilling:

- Etching: Removes unwanted copper to create the necessary circuit patterns.

- Drilling: Creates holes (vias) that connect different layers of the PCB and provide mounting points for components.

Precision is key in both etching and drilling. Any inaccuracies can lead to faulty connections or short circuits, affecting the board’s functionality.

5. Plating and Finishing

These stages involve plating and finishing to complete the board:

- Plating: A conductive coating, usually copper, is applied to the drilled holes and board surface to ensure proper electrical connectivity.

- Solder Mask Application: Protects the copper traces from oxidation and prevents short circuits during component soldering.

- Silkscreen Printing: Labels component locations, making assembly easier and reducing the risk of errors.

These touches are crucial for both the performance and durability of the PCB, ensuring it meets the required standards before final assembly.

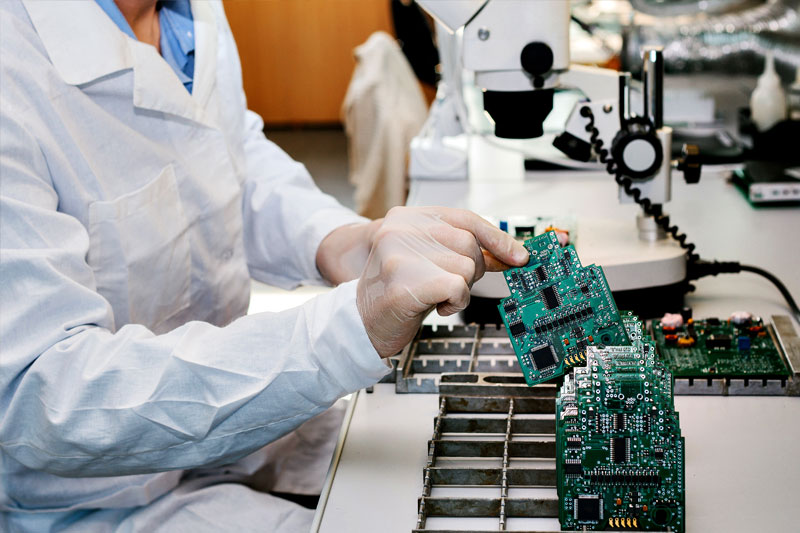

6. Component Placement

After the PCB is fabricated and finished, the next step is placing the components onto the board.

For modern PCBs, components are placed automatically. Machines place components like resistors, capacitors, and integrated circuits with high precision onto the PCB based on the design layout.

Given the shrinking size of PCBs and the importance of accurate placement, automation is king when it comes to component placement. Misplaced components can lead to malfunctioning circuits or even damage during the assembly process.

7. Quality Checks

Quality is continuously being checked during the entire production process, but there are, of course, final checks performed before the board is shipped to customers. These include:

- Visual Inspection: To check for visible defects such as misaligned components, incomplete solder joints, or damaged traces.

- Electrical Testing: Automated test equipment is used to verify the electrical integrity of the board, ensuring that all connections are correct and that there are no short circuits.

- Functional Testing: Simulates the PCB’s operation within its intended application to confirm that it performs as expected under real-world conditions.

With this explanation of the PCB fabrication process complete, let’s explore the specific layers that make up the structure of a PCB.

What Are the Layers of PCB Fabrication?

The structure of a PCB is defined by its layers, each of which plays a critical role in the board’s functionality and performance.

At the core of PCB fabrication is the careful assembly of these layers, which can range from simple single-layer boards to complex multilayer structures.

Substrate Layers

Substrate layers (also called core layers) form the foundation of the PCB. They can be single or double-sided. They consist of rigid base materials, typically FR-4, that provide structural integrity and separate the conductive layers of the PCB.

Substrates provide the mechanical support necessary for the board’s stability as well as the insulating properties needed for the board to function.

Prepreg Layers

Prepreg is a dielectric (insulating) material that is used to either bind two substrate layers together or to bind substrates together with conductive copper foil layers. For this reason, it is sometimes called a binding layer.

Prepreg is an advanced material with many useful qualities for PCB manufacturers. Through different processes, it can be modified to different levels of conductivity or drilled through to connect different layers.

Conductive Layers

The conductive layers of a PCB are created by laying thin sheets of copper on top of the prepreg layers. Excess copper is removed using the process known as etching, which we mentioned above. What remains are the desired electrical pathways that connect components on the PCB’s surface.

Solder Mask and Silkscreen Layers

After the pathways are etched onto a PCB, they are protected using a solder mask. This is a thin layer of polymer that acts as a barrier stopping unwanted electrical connections between copper features on a board.

The final layer is a silkscreen. Silkscreens are labels that indicate where components are to be placed on the completed board.

The intricacies of PCB layers highlight the importance of precise PCB fabrication techniques, particularly when creating multilayer PCBs. Now, we can talk about how these processes can affect PCB fabrication timelines.

How Long Does PCB Fabrication Take?

The timeline for PCB fabrication can vary widely depending on the complexity of the design, the number of layers, and the specific requirements of the project. In general, a solid PCB manufacturer can produce prototypes within 24 hours and complete production within 5-7 days.

Understanding the factors that influence PCB fabrication time will help you plan and manage project deadlines.

Several key aspects play a role in determining how long the process will take:

- Design Complexity: More intricate designs with higher layer counts require additional time for each step, including layering, drilling, and testing.

- Material Availability: Sourcing materials can lead to delays, especially if components need to be ordered from multiple suppliers.

- Order Volume: Larger production runs take longer to complete, while smaller batches or prototypes can often be fabricated more quickly.

Required Finishes: Special finishes or treatments, such as gold plating or conformal coatings, add time to the process due to the additional steps involved.

PCB Prototyping

Prototyping is a stage in PCB fabrication where manufacturers build, refine, and redesign PCBs to optimize them before full-scale production.

Standard prototyping can take several days to weeks, depending on the complexity.

Quick Turn PCB Prototyping

Quick-turn prototyping services accelerate the development process, often delivering prototypes in one day or less, which can significantly increase the speed of development.

Turnkey vs. Traditional PCB Fabrication

The choice between turnkey and traditional PCB fabrication also affects the timeline.

Turnkey PCB fabrication, where the manufacturer handles everything from component sourcing to assembly, can streamline production and reduce lead times, whereas traditional fabrication might involve multiple suppliers and stages, potentially extending the overall time required.

Now that you have a solid grasp on both the manufacturing process and the timelines involved, we can get to the final factor: cost.

What are the Cost Factors of PCB Fabrication?

The final cost of PCB fabrication will depend on factors ranging from supply chain constraints to process complexity. Here are some of the major factors you’ll need to understand to properly judge a fair cost for PCB fabrication:

Materials

The choice of materials is a significant factor in the cost of PCB fabrication. High-quality substrates, copper thickness, and specialized finishes, such as gold plating or high-temperature laminates, can all increase costs.

In addition, using advanced materials to meet specific industry standards or environmental requirements can further raise the price. These materials are often necessary for applications in demanding environments, such as aerospace or medical devices, but they come at a premium.

Complexity

The complexity of the PCB design plays a major role in determining the cost. More intricate designs with higher layer counts, finer pitch components, and dense routing require more sophisticated fabrication processes, which can increase production time and cost.

Specific design features also add to the complexity and expense, including:

- Blind and buried vias

- Controlled impedance

- Tight tolerances for critical components

Each of these elements demands additional time and precision during fabrication, leading to higher overall costs.

Volume

The scale of production has a significant impact on the cost per unit.

- Larger production runs benefit from economies of scale, where the cost per PCB decreases as the volume increases.

- Conversely, smaller batches or prototypes are often more expensive on a per-unit basis.

Planning production volumes carefully can help manage costs more effectively.

Lead Time Required

The urgency of the project can also affect costs. Rush orders or quick-turn fabrication services often come with a premium, as manufacturers may need to prioritize the order, work overtime, or use expedited shipping for materials.

By allowing for standard lead times, you can avoid these additional expenses. Proper planning and scheduling can significantly reduce the overall cost of PCB fabrication.

Choose a Trusted PCB Manufacturer: Imagineering

Materials, processes, timelines, and costs can all be balanced into a single optimized process for your next PCB. The only thing standing in the way is your knowledge of the PCB fabrication process. Using what we’ve outlined in this guide, you can dig deeper into the PCB fabrication process until you’re ready to start planning.

When that time comes, Imagineering is ready and waiting to help.

For 38 years we’ve been manufacturing and assembling the highest quality PCBs. We have expertise in creating PCBs for use in any industry and the certifications to prove it.

At the beginning of your next PCB fabrication process? Contact our experts and let us know what you’re building.