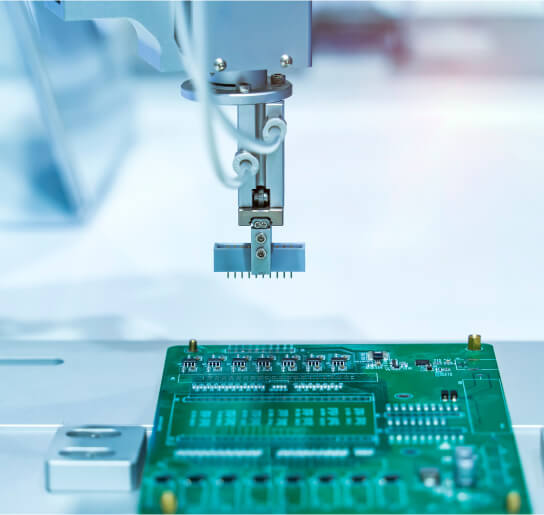

Whether you're trying to get your latest product to market quickly, or just need a few boards to prototype your personal project, lmagineering is capable of producing industry-standard PCBs for any application.

We offer fully-certified, high-quality PCBs at any production volume you need, and we do it with a 100% on-time guarantee.

With production facilities at our Illinois headquarters and offshore facilities, we’re able to offer same-day prototypes and production in 5-7 days.

lmagineering offers multi-layer rigid and flex PCB fabrication.

We make the most of smaller components with our HDI technology.

We can produce PCBs with a minimum board thickness of 4 mil (0.004″) and a maximum thickness of 240 mil (0.240″).

Materials available include:

Dimensions:

Finishes:

Soldermask:

Up to 4 oz. copper thickness available.

Trace Width and Spacing:

Whether you’re sending us materials and build kits from your own supply chain, or relying on our full-service turnkey fabrication, we offer the following assembly services:

Class II and Class Ill Inspection: We adhere to stringent industry standards

for high-reliability applications.

Part of our dedication to quality is staying on top of all relevant industry standards.

We are:

For nearly 40 years, we’ve been focused on delivering high-quality, fully certified PCBs for customers in every industry. From hobbyist builders to international electronics manufacturers, we’ve experienced every roadblock and have the tools and experience needed to overcome them.

We’ve got firsthand knowledge in:

If you’re unsure if we have the capabilities to produce what you need, get in touch with one of our experts and let’s see if we’re a good fit.

Our international presence affords us access to economies of scale. That means we’re ready and willing to handle any volume of production you need. Whether you just need a prototype, or you’re looking for a full production run, we’re ready to help.

We have state of the art facilities located right here in the United States at our Elk Grove, IL headquarters. To support larger production runs, we also have offshore facilities.

We promise to meet any delivery schedule you need without compromise.

Our dedicated support team is ready to assist our clients throughout the project lifecycle.

HQ

1389 Brumlow Ave

Southlake, TX 76092

PCB Assembly

2425 Touhy Ave

Elk Grove Village, IL 60007

Phone:(847)806-0003

Email:Sales@PCBnet.com

ITAR Registered

AS9100D/ISO9001:2015

SAM Registered

RoHS Compliant

Copyright © 2023 Imagineering, Inc Web Design by Solid Digital