Control costs and get to market faster with PCB design, components, assembly, and testing all under one roof.

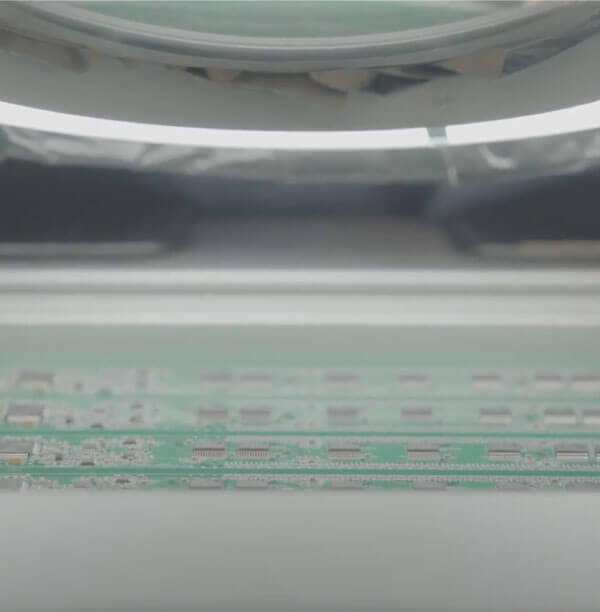

Our full-service turnkey PCB assembly is designed to help you take your product idea from conception to completion in less time, while guaranteeing quality and reducing overhead.

We’ll handle everything including assisting with the design phase, 24-hour rapid prototyping, ordering components, assembling the board, performing industry-standard quality testing, and shipping your finished PCBs.

Turnkey services are ideal for anyone looking to:

Here’s one universal truth in the world of manufacturing: for every additional hand involved in the process, new risks are introduced. Working with multiple suppliers, vendors, and assemblers for your PCBs means each individual is less invested in the final product.

Even if your vendors are reliable, coordination between them is another obstacle to a smooth production run. While one part of the process may be running perfectly, another can cause bottlenecks and issues that are difficult to even identify, let alone fix.

Every problem that crops up delays your production and jeopardizes quality. For those trying to stay on top of competitive industries, problems like these can be the difference between sinking and swimming.

When you choose Imagineering’s full-service turnkey PCB assembly, you’re consolidating every aspect of the PCB production process under one roof. From start to finish, we take on every responsibility including:

Imagineering’s turnkey PCB assembly services aren’t just about churning out PCBs quickly and cheaply. Our primary goal is to produce the highest quality PCBs for any application.

We accomplish this goal through a combination of decades of experience, cutting-edge technology, and a dedication to serving our customers.

Since 1986, Imagineering has been focused on learning how to create the highest quality PCBs for over 30,000 unique customers. We’ve worked with customers in every industry including aerospace, medical devices, and defense. If there’s a roadblock to your success, we’ll spot it early and help you get around it to ensure a smooth PCB production run.

The key to modern PCB production is technology. Thanks to our constant investment in the latest hardware and software systems, we’re capable of producing the PCBs to meet any standard.

Our assembly capabilities include:

We guarantee the quality of your boards through an on-going QA process that includes:

Contact us and we’ll let you know if we can handle it.

Part of our dedication to quality is staying on top of all relevant industry standards. We are:

At Imagineering, we value our customer relationships above all else. We know that the best way for us to meet our goals is to help our customers meet theirs. That’s why we go above and beyond to ensure you’re happy and satisfied with the products you receive.

When you choose to work with Imagineering, you get access to:

DFM/DFA/CAM Checks: These are computer-aided pre-production checks that ensure your designs are optimized for manufacturing and assembly. We use them to spot issues early and fix them before any work starts. This optimizes your boards while reducing costs and eliminating the chance of last-minute problems.

Off-Shore Production: Our global presence in Korea, and Taiwan enables economies of scale. This helps us control costs while also accommodating larger and more complex production runs.

Responsive Customer Service: Without our customers, we can’t meet our goals. That’s why every Imagineering customer has access to our dedicated support team that is on hand to help identify and resolve issues as should they ever arise.

HQ

1389 Brumlow Ave

Southlake, TX 76092

PCB Assembly

2425 Touhy Ave

Elk Grove Village, IL 60007

Phone:(847)806-0003

Email:Sales@PCBnet.com

ITAR Registered

AS9100D/ISO9001:2015

SAM Registered

RoHS Compliant

Copyright © 2023 Imagineering, Inc Web Design by Solid Digital