Great products take time to develop.

As the old saying goes, the map is not the territory. When designing products, wrong turns will be made.

The question is not how to avoid wrong turns but recognize and correct errors before wasting time and resources on a batch of products that don’t function. The faster you can do this, the faster you’ll be ready to market.

The next time your company churns out an idea for a cutting-edge product, how can you be sure you’re moving through the PCB prototyping process as efficiently as possible?

What plan do you have to ensure that your innovative design hits the market before your competitors can catch up?

Today’s guide is here to help you understand the purpose of quick-turn PCB prototyping, how it works, and how to choose a reliable and experienced quick-turn PCB manufacturer for prototyping.

Understanding Quick-Turn PCB Prototypes

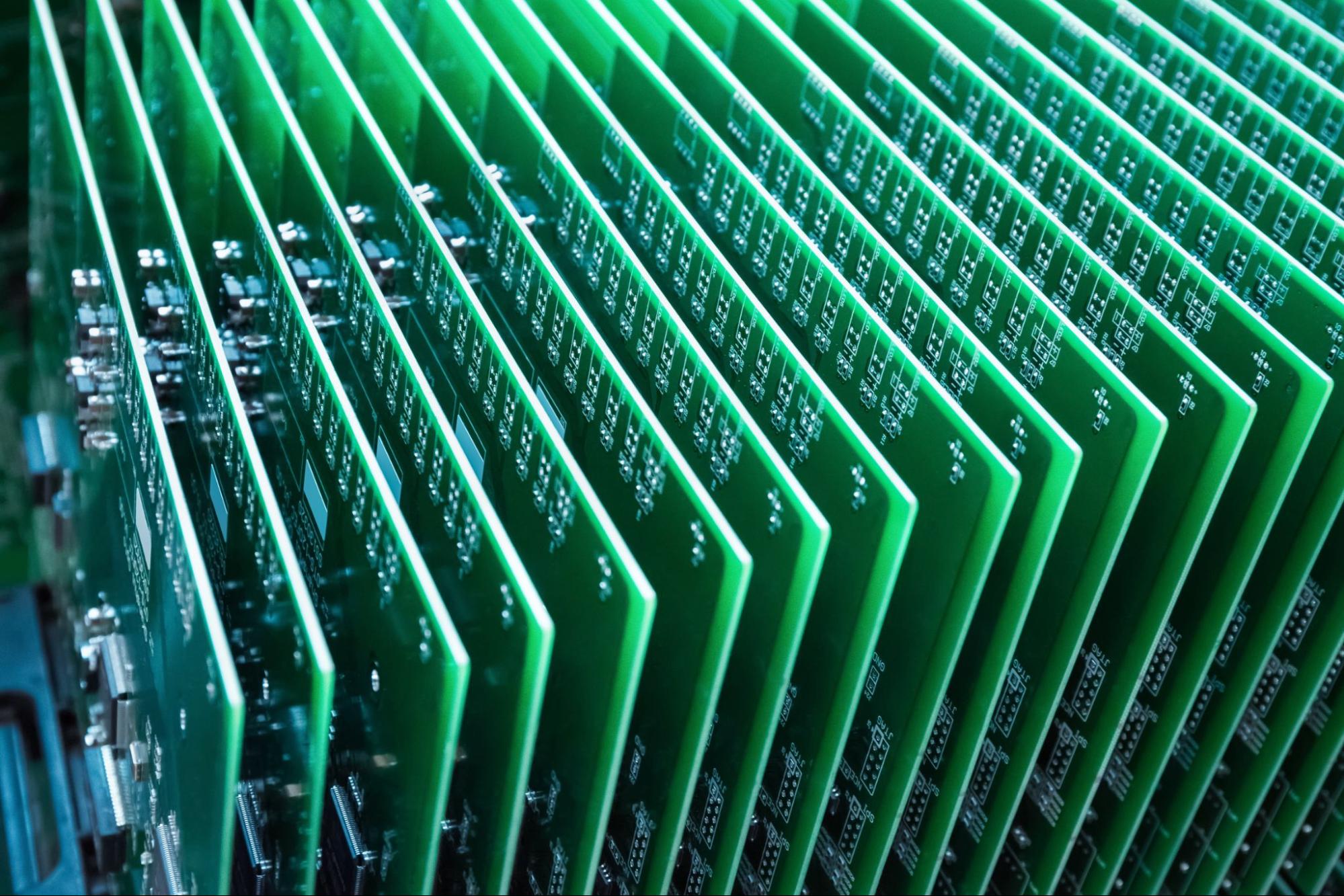

Quick-turn PCB prototyping refers to rapidly producing small quantities of PCB prototype boards to test and validate designs.

Key Features of Quick-Turn PCB Prototypes

The main characteristic of quick-turn PCB prototypes is the speed at which they can be produced. This makes them ideal for projects that must develop quickly to stay ahead in competitive marketplaces.

Other than speed, quick-turn PCB prototypes share features like:

- High Flexibility

- Long-Term ROI (by capturing and retaining a first-mover advantage)

- Suitability for Small Quantities

The Quick-Turn PCB Prototyping Process Explained

The process starts with design files that your engineers will create and ends with your manufacturer delivering the prototype PCBs.

1. Design Files and Specifications

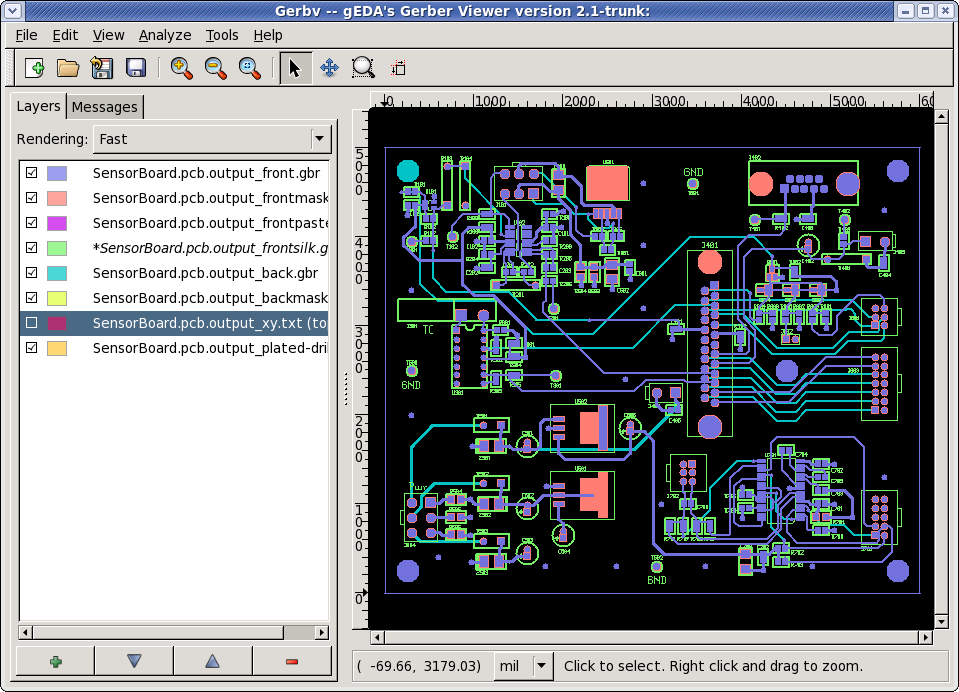

You’ll send design files to your manufacturer for review. These will include Gerber files, centroid files, and any specific requirements for the prototype, including a bill of materials (BOM.)

2. Design for Manufacturability (DFM) Check

The manufacturer should perform a DFM check to ensure the design can be effectively produced without any potential manufacturing issues.

3. Material Selection and Inventory Check

The manufacturer will ensure it has the appropriate materials in its inventory, including the requested PCB substrate and other components.

4. Prototype Manufacturing

Prototype manufacturing can commence at this step. The manufacturer will rapidly produce and assemble the requested PCB using advanced techniques.

5. Quality Control and Testing

Once produced, the manufacturer can perform a quality check to ensure the board is functional, high-quality, and meets specifications.

6. Shipping and Delivery

Once the prototypes pass the manufacturer’s quality testing, they’ll package and ship the prototype PCB to the tech company for evaluation.

Common Challenges During Quick-Turn PCB Prototyping and How to Overcome Them

Here are common problems that frequently arise during quick-turn prototyping and instructions on how to solve them.

Design Compatibility Issues

The design files may have compatibility issues with the manufacturer’s equipment or fabrication process.

To resolve this, we recommend you keep an open line of communication with the manufacturer from the outset. Share your design intent and your product’s specific needs, and be ready to find solutions as early as possible.

Component Availability

You may find that certain specialized components are not readily available in the manufacturer’s inventory, which can cause delays.

Be ready to collaborate with the manufacturer to find possible alternatives or consider using readily available components for the prototype.

Timely Shipping and Delivery

Meeting tight project deadlines is a key benefit to quick-turn prototyping, but this benefit can quickly become a pain point if your manufacturer doesn’t deliver on time.

In addition to learning about the manufacturer’s capabilities and materials inventory, ensuring they have a reputation for meeting their promises can save you time and resources.

Advantages of Quick-Turn PCB Prototype Boards

Industries like consumer electronics, medical devices, IoT, and robotics rely extensively on quick-turn PCBs when prototyping their products. Here are five reasons why:

Accelerated Product Development

Quick-turn prototypes bring ideas to life faster, enabling faster exploration of design concepts and functionalities.

Reduced Time-to-Market

Tech companies that utilize quick-turn PCB prototypes can identify and resolve design issues faster. This ensures a faster transition to the manufacturing phase and reduced time-to-market.

Faster Iterations and Rapid Testing

Designers will have more time to optimize designs and test new iterations. More iterations mean more testing and validation, enabling refined product designs and better performance.

More Efficient Design Flaw Identification

Identifying critical flaws early in the design process allows for addressing those issues promptly, preventing time-consuming modifications during mass production.

Mitigated Large-Scale Production Risk

Utilizing quick-turn PCB prototype boards, companies can reduce the risk of encountering critical flaws during mass production. This minimizes the chances of costly product recalls or extensive reworks after the product is on the market.

Are Quick-Turn PCB Prototypes Right for You?

Before you decide that a quick-turn PCB prototyping process is right for your next product development phase, here are 5 factors to consider.

1. Design Readiness and Complexity

If you’re using a well-established design that isn’t likely to need many changes or aren’t concerned with beating your competition to the market, a more traditional prototyping process may save you resources.

2. Manufacturer Capabilities

Different manufacturers do business in different ways. Before hiring them for your quick-turn PCB prototypes, you’ll need to make sure you’re working with a manufacturer that meets your unique needs:

- Their values and culture: why do they do what they do?

- Their ability to meet deadlines while producing a high-quality product.

- How long they’ve been in business, to gauge what sort of experience they may have with unique situations and requests.

- Finally, do they have a history of satisfied customers willing to vouch for their business?

3. Ensuring Quality and Reliability

To ensure that the manufacturer’s quality and reliability standards match with your company’s, get information like:

- A rundown of quality control procedures for each PCB they manufacture, including any specific testing they perform.

- Their criteria for verifying that prototypes meet specifications.

- What level of inspection do they utilize for component placement and soldering?

- The steps are taken to identify and rectify manufacturing defects.

- Whether they offer DFM checks.

4. Material and Technology Selection

Your engineers will have an idea of what the best substrate material will be for your applications, so ensure your manufacturer can meet that demand. Also, ensure the manufacturer can meet your design requirements, such as surface mount technology (SMT) or through-hole technology (THT).

5. Budget and Cost Considerations

Finally, make sure you understand what you’re getting into from a resource perspective. Quick-turn prototyping is flexible and fast but potentially costs more than a traditional process.

Evaluate your budget and balance it against the urgency of your project.

Designing PCBs Suitable for Quick-Turn Prototyping

To take full advantage of the speed and flexibility of quick-turn prototyping, keep these design best practices in mind.

Keep Designs Simple and Focused

This means avoiding unnecessary components or complexity that could hinder quick prototyping and increase the risk of errors.

Utilize standard components whenever possible. This will reduce lead times, ensure availability, and simplify the quick-turn process.

Follow DFM Guidelines

Communicate early with the manufacturer to ensure your designs meet their DFM guidelines. These guidelines will be specific to the manufacturer’s equipment, capabilities, and processes.

Ensure you’re meeting their guidelines for factors like:

- Trace width and clearance

- Component footprints

- Panelization

- Drill sizes and aspect ratios

- Manufacturable shapes

- Material selection

Ensure Proper Documentation

Thorough and accurate documentation will ensure a smooth manufacturing process conducive to a rapid turnaround for your PCB prototypes.

Ensure your manufacturer has access to the following:

- Gerber Files

- Bills of Materials (BOM)

- Centroid Files

- Assembly Files

- Any Special Requirements

- Revision Histories

- Test and Inspection Criteria

- Contact Information

Partner with Imagineering for Quick-Turn PCB Prototypes

Once your company has done the hard work of developing an idea for a revolutionary product you want in the market as soon as possible, the most important decision you’ll have to make is which quick-turn PCB manufacturer to work with.

As stated above, you’ll want a company with decades of experience, a sterling reputation, and all the capabilities to rapidly transform your idea into a tangible product.

Imagineering has the experience, knowledge, and specialization necessary to turn your design into a physical prototype within 24 hours and get your idea in production within 5-7 days.

We value our relationship with product designers and understand the importance of speed and accuracy in the prototyping process. That’s why we offer full DFM support, class II and III inspections, and can produce anywhere from 1 to 100,000 units depending on your needs.

Finally, as a one-stop shop, Imagineering offers production and assembly services with a 100% on-time guarantee.

If you want to work with us, check out our services page, or reach out today for a quote. Let’s turn your idea into a revolutionary product today.

FAQs About Quick-Turn PCB Prototypes

How Fast Can I Get a Quick-Turn Prototype?

Imagineering offers quick-turn prototype turnarounds in as little as 24 hours.

Can Quick-Turn Prototypes Guarantee High-Quality PCBs?

While quick-turn prototyping is a powerful tool for quickly and efficiently turning your ideas into a reality, only experienced manufacturers and skilled designers can guarantee high-quality PCBs.

Make sure you choose a manufacturer with a wealth of experience and knowledge to guide your quick-turn prototyping process.

What Are the Limitations of Quick-Turn PCB Prototyping?

The primary limitation of quick-turn prototyping is the cost factor.

Because quick-turn prototyping is focused more on speed and flexibility, there is a greater cost necessary to ensure proper standards are met and ensure only the highest quality products.

If your design is already well established or isn’t likely to need many revisions, a more standard prototyping process may be right for you.

What Are the Benefits of Quick-Turn PCB Prototyping?

Quick-turn PCB prototypes benefit from rapid turnaround and greater flexibility, which means your product can get to market faster.