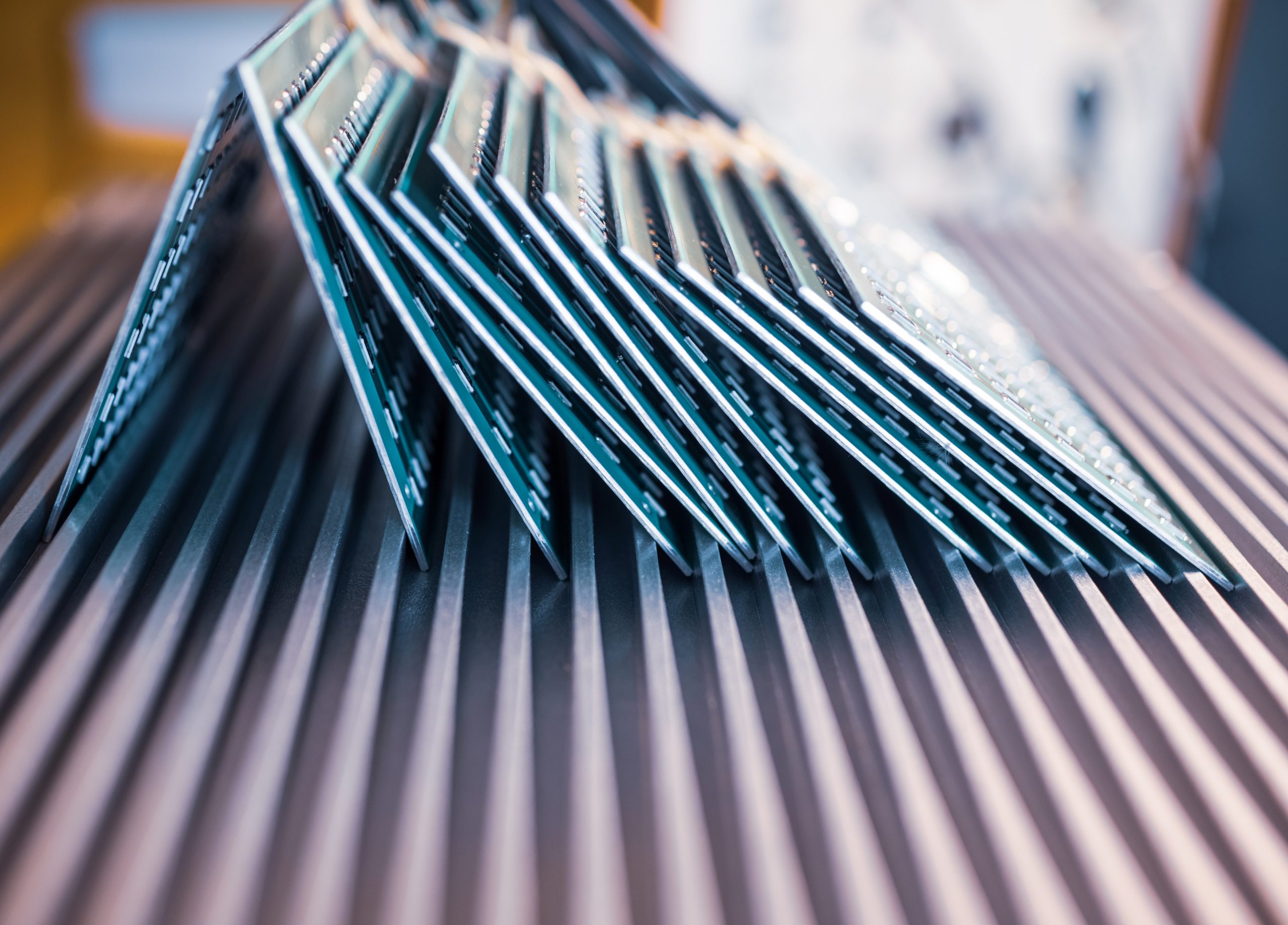

PCBs are the foundation for modern electronics. To keep up with a demanding marketplace, they need to be well-built, meet exact specifications, comply with stringent regulations, and be mass-produced.

All of this means you need a PCB supplier with a wide range of technical expertise.

Everything from design and prototyping to final quality checks needs to be completed with state-of-the-art technology. The entire process requires a large team of skilled engineers and technicians to ensure your boards are done on time and to a high standard.

Let’s take a closer look at all the ways technical expertise matters to your finished PCB.

Understanding the Importance of Technical Expertise in PCB Suppliers

Every step of the PCB production process is technically complex. Intricate knowledge is required for everything from design to assembly. This means two things:

- A supplier with a lot of technical expertise can greatly influence the final quality of the board.

- An expert PCB supplier will have the knowledge and skills necessary to avoid mistakes and get the boards done quickly and efficiently.

Expertise Directly Translates to Quality

Let’s say you have a board design that will be subject to high temperatures either during manufacturing or operation. For knowledgeable PCB suppliers, this is no problem at all. They know you’d need a substrate with a higher Tg (glass transition temperature).

However, if your PCB supplier used a low Tg substrate, your board might encounter complications during manufacturing. Worse, it could malfunction in your customer’s hands.

Expert PCB suppliers avoid problems like these. Their skilled engineers and technicians can foresee potential design and manufacturing challenges and address them before they escalate into costly errors.

Technical Proficiency = Manufacturing Efficiency

The ability to carry out comprehensive testing and quality assurance is a requirement for efficiency.

Expert PCB suppliers use advanced testing methods like Automated Optical Inspection (AOI) and X-ray inspection to detect problems that compromise PCB performance. Better yet, they can employ them during the manufacturing process, ensuring that no time is wasted in rectifying errors that arise.

This reduces the time and resources spent on PCB production, allowing you to focus on designing and marketing your products.

How Modern PCB Suppliers Combine Speed with Efficiency

A combination of flexible assembly capabilities and strict adherence to precise tolerances is required for modern PCB production. Achieving this balance requires a mixture of skilled engineers and state-of-the-art production capabilities.

Thanks to their dedication and knowledge, PCB suppliers with a high level of expertise enable:

Quick Transitions

Rapid prototyping is essential for iterative design and refinement. Modern PCB suppliers offer same-day prototypes and, in some cases, same-day production volumes, helping you get to the market ahead of the competition.

In addition to prototyping and production, your company needs to be able to scale according to market demand. Expert PCB suppliers give you the agility to shift from low-volume to high-volume production without sacrificing quality.

Finally, you may need to quickly transition from one design to the next to accommodate major upgrades or changes to your products. Having a PCB supplier with a range of assembly types, such as Surface-Mount Technology (SMT), Through-Hole (THT), and flexible circuit assemblies, accommodates diverse product requirements.

Expertise means flexibility and versatility, two keys to succeeding in the constantly changing electronics industry.

Uncompromising Precision

You don’t just need your boards done quickly. You also need them done with precision.

Expert PCB suppliers know that:

- Adhering to stringent assembly tolerances is critical for compatibility with other electronic components and for the functionality of the final product.

- Exact component placement and soldering can also significantly impact the performance of the PCB.

- Utilizing materials that can withstand the rigors of use, such as maintaining precise material thickness per design requirements, is fundamental for product durability and effectiveness.

Without this precision, speed means nothing. Choosing a PCB supplier that can meet these standards every time saves time and contributes to a higher quality final product.

Your PCB Supplier’s Material Selections Can Help with Compliance and Marketability

Adhering to compliance standards isn’t just a good way to avoid fines and penalties. With the right expertise, they can also mean better quality and more marketable PCBs.

RoHS Compliance

The RoHS (Restriction of Hazardous Substances) directive restricts the use of specific hazardous materials in electrical and electronic products. PCB suppliers who help you meet this directive not only ensure environmental safety and reduce toxic waste but also open doors to markets like the EU, where compliance is mandatory.

Lead-Free Soldering

There’s been a global shift towards lead-free soldering practices driven by environmental concerns and health-related issues associated with lead.

Using lead-free solders ensures you’re in compliance with global regulations and helps improve the recyclability of your products.

Halogen-Free Options

As environmental and health awareness increases, the demand for halogen-free PCBs has risen as well.

Halogen compounds in PCBs can release toxic gases when exposed to high temperatures. Halogen-free PCBs are safer for both the environment and the end-users, providing a significant advantage in consumer electronics where safety and environmental impact are key concerns.

Imagineering: Your Expert PCB Supplier

Quick-turn prototypes, flexible manufacturing options, and a wide range of materials are all essential tools for your PCB supplier to have. They prove a level of technical expertise that will help you turn that electronic device you’re imagining into a finished product.

Imagineering has this expertise.

We’ve spent 37 years delivering high-quality, cutting-edge PCBs to our customers. We’ve been successful because we prioritize technical expertise and pride ourselves in utilizing the latest technical developments to build better boards. If you’re looking for your next PCB supplier, get in contact with Imagineering today and find out how our technical expertise can contribute to your project.