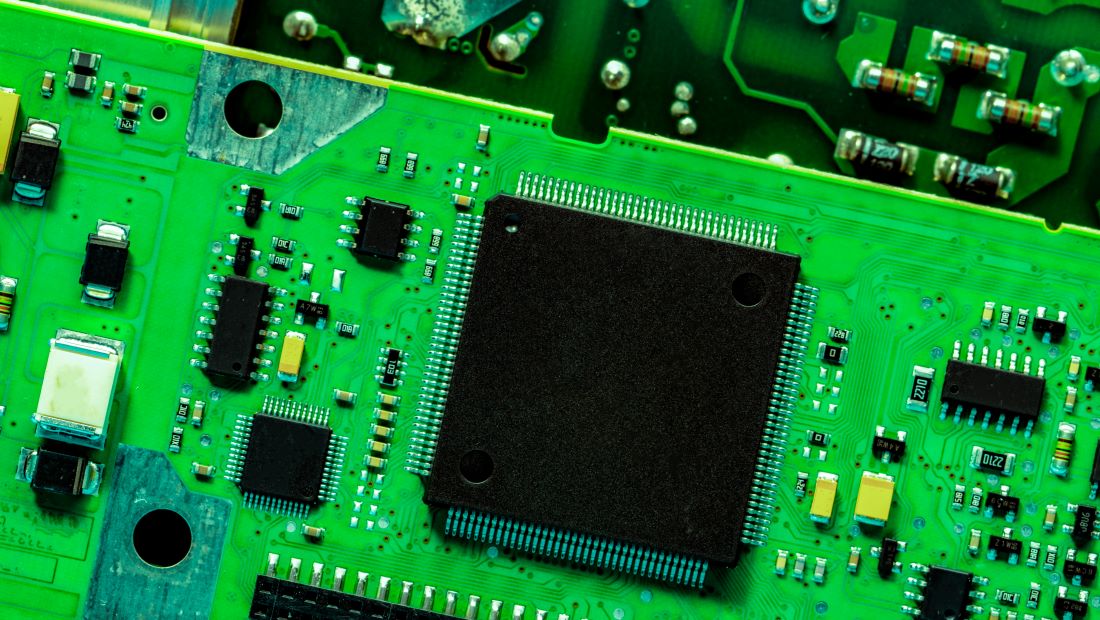

The holiday season is in full swing. The air is crisp, the sun is setting too early in the day, and the PCB industry is wrapping up another year of growth and technological innovations. It’s been a year of trends, surprises, and some impressive headlines from around the world.

As the year winds down, we at Imagineering want to keep our eyes towards the horizon. What does the future look like for the PCB industry? What new innovations will gain a foothold next year, and how will the industry look different 12 months from now?

Let’s take a look at some of the trends in PCB manufacturing that we expect to gain steam in 2024.

The Rise of Sustainability in PCB Assembly

Every industry in the world is shifting its focus toward sustainability, and the PCB industry is no different. Expect the focus on environmentally friendly PCB manufacturing to continue in 2024.

PCBs Are Now Dissolvable

As we covered in our blog back in October, Jiva Materials made headlines earlier this year by developing the world’s first water-soluble PCB, the Soluboard. The board is made of a flax-fiber-based composite and represents a massive leap forward in the PCB industry’s push towards reducing e-waste.

The full potential of dissolvable boards is still being discovered, but expect to see them used in prototyping and consumer electronics, where environmentally-conscious consumers will pay extra for devices that align with their eco-friendly lifestyles.

PCB Assembly Innovations Powering the IoT Surge in 2024

The IoT’s dominance in our daily lives continues to grow. As we near the middle of the decade, the practical use of IoT now spans across nearly every industry including smart home devices, healthcare, and even public services like traffic and waste management.

PCB manufacturers look for ways to accommodate the needs of the growing IoT market with smaller, more densely packed, and more flexible products. The need to dissipate heat, include Wi-Fi and Bluetooth modules, and separate sensors from power signals poses a challenge to PCB designers that will spur further innovation in the coming year.

The Surge of Flex PCBs in 2024 and the Cost Challenge Ahead

Though the pace of miniaturization isn’t as rapid as it once was, devices are still getting smaller every year. The need for smaller and more powerful PCBs that can fit innovative designs is a pressing issue, and the use of flexible PCBs to suit these innovations has become a favored solution for electronics manufacturers. Flex PCBs bend, twist, and fit into any shape of case or housing while including the reliability and performance of traditional PCBs. This has made them invaluable tools for designers of medical devices, automakers, and aerospace engineers. So, with all of the advantages of traditional PCBs and no drawbacks, what’s the main challenge for flex PCB manufacturers to overcome? Cost. Flexible PBCs require unique manufacturing and assembly processes as well as special materials. This makes them more expensive than rigid PCBs for similar performance. As manufacturers continue to find new ways to produce these lightweight boards, expect to see the use of flexible PCBs rise in 2024. The PCB market may not have grown as quickly in 2023 as it has in years past, but the world isn’t likely to desire less electronics anytime soon. With the rise of IoT, AI, and machine learning, the need for new and powerful PCBs and other electronic components will soon reach all-time highs. This is great news for PCB manufacturers, but those in the West are facing fierce competition from countries in the Asian Pacific. The APAC region accounted for nearly half of the revenue share, according to the most recent industry reports. In 2024, look for North America and Europe to turn to its most tried and tested strategy: innovation. PCB assembly in the West will find ways to cut costs while maintaining high-quality and reliable outputs and recover big chunks of market share. ChatGPT, Midjourney, Grok, DALL-E, TensorFlow. These are a few examples of some incredible AI tools that have gained prominence in the public sphere in the last year. However, they’re far from the final step in humanity’s journey to unlocking and conquering artificial intelligence. In the future, AI may control everything from our cities to our healthcare, education, and especially math, science, and engineering. To accomplish this, engineers and scientists will need the latest and greatest PCB technology. Perfecting manufacturing techniques like HDI flex PCBs and continuing to refine and perfect the materials within PCBs will enable AI to solve the problems of the future in 2024 and beyond. As we bid farewell to 2023 and embrace the exciting prospects of 2024 in the PCB assembly landscape, one thing is clear – innovation is the driving force that propels us into the future. From dissolvable boards heralding a sustainable revolution to the surge of flexible PCBs meeting the demands of miniaturization, the industry is evolving at a rapid pace. As North America and Europe gear up to reclaim PCB dominance amidst APAC competition and AI’s power surge continues, Imagineering stands at the forefront, ready to shape the technological frontier.North America and Europe Gear Up to Reclaim PCB Dominance in 2024 Amidst APAC Competition

AI’s Power Surge

Imagineering: Powering the Future of Technology in 2024