Design for manufacturing (DFM), or design for manufacturability, is a set of practices for designing products that make them easy to manufacture. In particular, it allows engineers to address potential problems in the design phase where they’re less expensive to fix.

Virtually all engineering disciplines use DFM, although its implementation varies significantly according to the manufacturing technology. Manufacturing processes such as those used in a printed circuit board (PCB) have guidelines for DFM practices, including specific rules, checks, and tolerances.

Understanding DFM Principles

The principles of DFM assist in relating manufacturing problems to design, which benefits the manufacturing process. Here are the categories for which the design for manufacturing gets classified:

- Process

- Design

- Material

- Environment

- Testing

Process

Selecting the best manufacturing process for a particular product requires carefully considering general factors like cost and production volume. Additional product-specific factors include materials, surface finish, tolerance, and post-processing requirements. A PCB maker must finalize the manufacturing process first, as the other four types of DFM principles depend highly on it.

They must also carefully analyze the available manufacturing options to identify the best option rather than simply selecting the least expensive method. A cheaper manufacturing process often produces PCBs with a shorter life expectancy, resulting in a lower return on investment (ROI).

For example, tolerances that are too loose result in an inferior product that increases machine costs without increasing the quality. Tolerances can greatly impact a PCB’s final production cost, so catching product errors early in manufacturing is essential.

Design

Product design is crucial to applying DFM principles in PCB manufacture because even minor modifications can greatly affect product costs and lead times.

Analyzing designs with DFM tools is thus vital to remaining competitive. For example, it may seem that reducing the thickness of a plastic component is always desirable, provided it still has the required structural strength.

However, it’s often more economical to manufacture components with uniform thickness in the long run, regardless of their strength requirements.

Material

Engineers must select the materials they’ll use early in the design process, including their grade and form.

They should consider a variety of properties, such as strength, thermal/electrical resistance, and machinability, to determine the best choice.

Materials like metals are available in various forms, such as bar stock, plates, strips, and sheets. The properties of these forms can differ significantly, even when the material itself is the same.

For example, buying aluminum by the plate costs about twice as much as in bar stock costs.

Environment

The expected operating environment greatly affects a product’s quality standards. A PCB that needs to run in a dusty area must be built to higher specifications, especially with respect to heat tolerance and airflow. However, DFM principles require designers to ensure that quality goals are reasonable, as manufacturing costs are also a critical consideration.

For example, 5083 aluminum is often a requirement for marine applications due to its high corrosion resistance. Still, it’s an uneconomical choice for environments that don’t have a high risk of corrosion.

Testing

PCB manufacturers must keep testing in mind during the design phase to avoid problems during manufacture. An inexpensive product won’t ever reach the market if it can’t meet its testing standards.

DFM principles recommend compliance testing on a design before it enters mass production, as correcting these problems is far more expensive at the end of product development. This type of testing should also be non-destructive to ensure the test piece is fully functional afterward.

What are the Benefits of DFM?

Greater quality is probably the most fundamental benefit of DFM because it ensures the manufacturer designs products it can build. DFM also increases manufacturing speed because a well-designed part allows tools to function efficiently.

In addition, it cuts costs by reducing the time and labor needed to make parts. Furthermore, DFM increases the possibilities for automation by reducing the need for manufacturing oversight.

Key DFM Principles for Product Design

The key DFM principles for product design include the following:

- Manufacturability

- Assembly

- Reliability

- Testing

- Serviceability

Manufacturability with DFM Principals

Manufacturability refers to the ease of manufacturing a product, which is highly desirable in DFM. Making a better product at a lower cost is a primary goal in manufacturing, whether for a single part, the entire product, or the assembly process. DFM principles for manufacturability help product designers choose the methods for making a part.

Assembly with DFM Principals

The goal of designing for assembly is to make a part easy to put together. This practice primarily involves minimizing the number of parts, generally reducing testing and maintenance requirements.

A part should only be separate from the rest of the product if a specific reason exists for doing so. For example, a part that needs to move relative to the rest of the product must be separated.

Reliability with DFM Principals

Designers should integrate the DFR principle of reliability into the entire design process. Reliability measures are specific to each part and depend on the assembled product. Reliability principles require designers to identify the cause of each failure and work to minimize that risk so the failure doesn’t occur within the product’s lifecycle.

Specific techniques for testing and designing reliable products include failure mode and effects analysis (FMEA) and fault tree analysis (FTA). Reliability engineers have many other tools and only use the ones appropriate for a particular case.

Testing with DFM Principals

Product design testing ensures the design meets pre-defined standards. Testing all aspects of a PCB design isn’t practical, so engineers must develop methods of making testing during design easier and less expensive. This process aims to detect design defects with minimal impact on the assembly and packaging phases.

Serviceability with DFM Principals

Serviceability is about making the product easier to maintain, including preventative maintenance and repairs. Engineers often do this by building features that show the product’s condition. For example, a compressor may include a sight glass that shows its oil level, facilitating preventative maintenance.

Product design can also help with breakdowns by allowing easier access to parts most likely fail first. For example, accessing a vehicle’s spark plugs is usually much easier than accessing fan belts because plugs tend to wear out faster than belts.

Modular design is another key aspect of serviceability, as it allows repair technicians to replace only the failed part. For example, they should be able to replace just a faulty temperature sensor on a central air conditioner instead of also replacing its PCB.

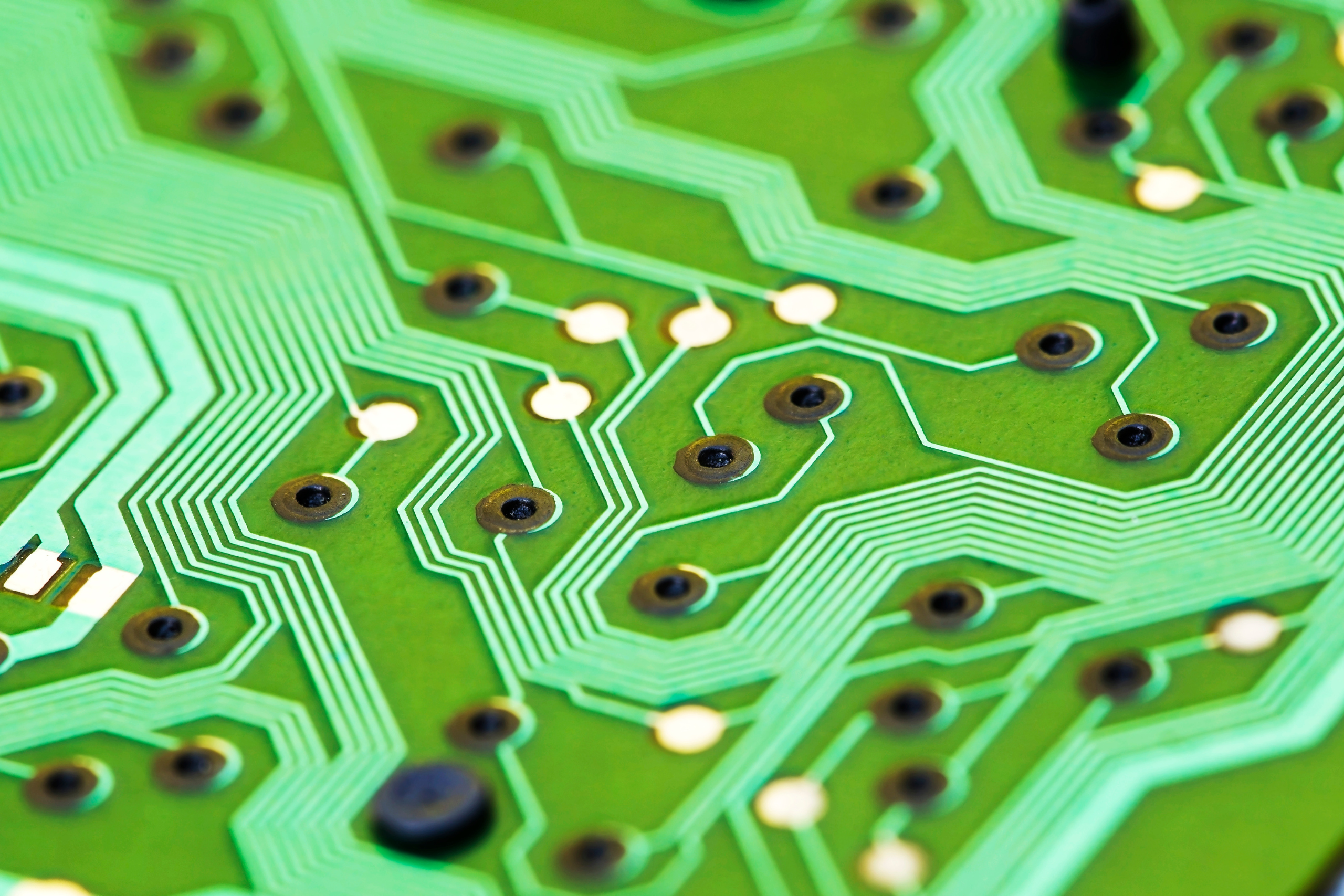

What are the DFM Principles for PCB Design?

The use of DFM in PCB design results in a set of guidelines intended to ensure manufacturability. This process addresses potential manufacturing problems during the design phase by accounting for this industry’s capabilities, which are constantly evolving. In particular, processes like surface-mount technology (SMT) and soldering are becoming more automated, generally lowering costs over the long term.

DFM principles that are specific to PCB design include the following:

- PCB layout

- Signal integrity

- Thermal management

- Mechanical considerations

DFM principles help designers keep PCB specifications within a layout, which becomes more important as the size of PCBs decreases. For example, incorporating existing components into a smaller design often results in issues like acid traps and insufficient edge clearance. Maintaining the high signal integrity needed by today’s PCBs also requires manufacturers to place and route circuits according to a design that best facilitates transmitting those signals.

Thermal management is another area that becomes more critical as PCBs get smaller, requiring DFM guidelines to consider factors like the operating environment and properties of semiconductor packages during the design phase. Mechanical considerations in PCB design are primarily related to stress, which designers should attempt to distribute as evenly as possible.

Tips for Implementing DFM Principles in Product Design

DFM is a great way to improve quality while cutting costs, but implementing it can present a challenge. This process consists of three distinct phases, including early integration of DFM, identifying additional opportunities, and broadening the scope of DFM.

The early stage of the design process is the best time to implement DFM because it allows designers to make changes quickly and at a lower cost. Changing the design later is particularly difficult when it requires retooling. Thorough manufacturability evaluations are usually the first step in integrating DFM into the design.

A strong DFM program should discover multiple opportunities for improving product design. This process often involves closer cooperation between designers and manufacturers, allowing them to identify sources of material wastage. Designers can also work with suppliers to determine the cost and availability of alternative materials.

Broadening the scope of DFM becomes more accessible as manufacturing efficiency increases, allowing manufacturers to focus on other aspects of improving manufacturability. Common areas for increasing scope include product weight and dimensions, tooling, and labor costs. Optimizing these areas can also improve the organization’s overall efficiency.

Conclusion

DFM is a crucial aspect of product design, especially in today’s fast-paced world, where time-to-market is critical. By leveraging DFM, you can identify and solve potential issues early in the design process, resulting in better quality products and increased efficiency. The use of DFM in PCB manufacturing is primarily driven by the ongoing need for miniaturization, resulting in numerous design constraints. It also means that designers and manufacturers must work together more closely to achieve further improvements in this maturing technology.

At Imagineering, we’re committed to providing our clients with the best possible service and support from design to production. Our team of experts is well-versed in DFM and can help you identify and solve any potential issues in your PCB design early on. If you are ready to get started, contact us today to receive a custom quote tailored to your specific needs.

Ready to create your prototype? Take advantage of our special offer and receive a free prototype with your next production order. It’s the perfect opportunity to test your design and make any necessary adjustments before moving forward with mass production.