Surface Mount Technology (SMT) is at the heart of nearly every modern electronic device. It’s why your smartphone is sleek, why your laptop is powerful, and why advanced industrial systems can process data at lightning speed.

If you manufacture electronics, you need to understand SMT. Knowing how it works can help you optimize designs, choose the right supplier, and troubleshoot assembly issues.

In this guide, we’ll cover SMT, why it dominates PCB assembly, how the process works, and where it’s headed next.

What is Surface Mount Technology?

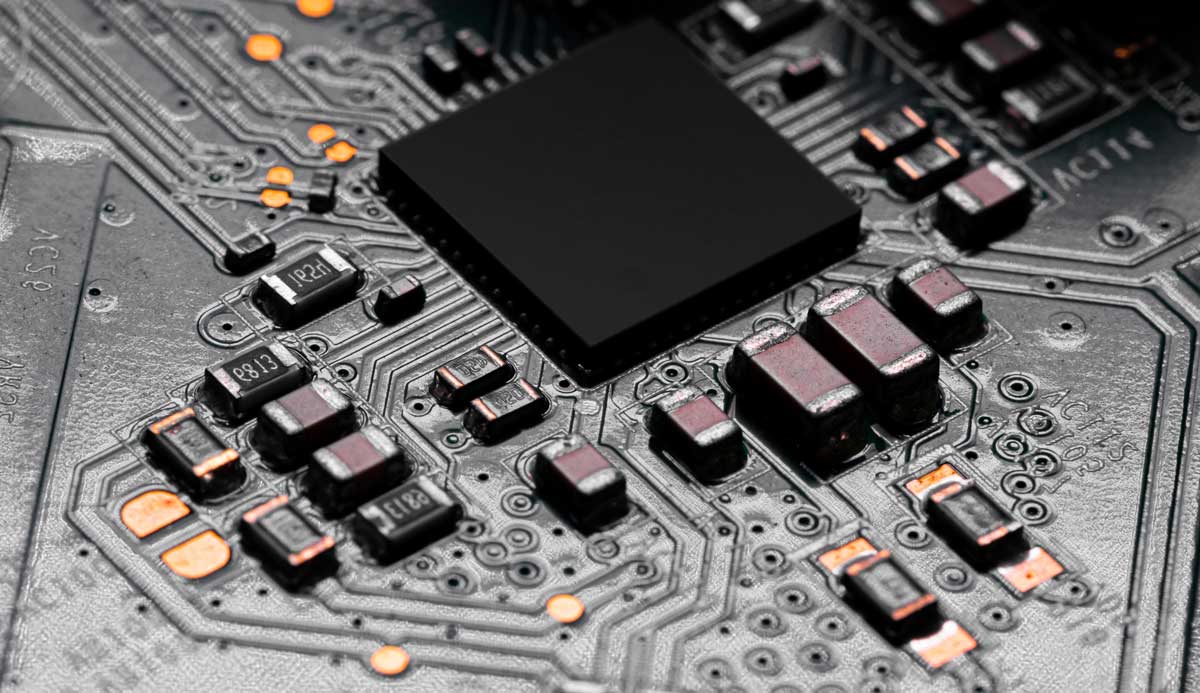

Surface mount technology is a method of PCB assembly where components are placed directly onto the surface of the board rather than inserted through drilled holes. This allows for smaller, more efficient circuit designs and makes high-speed automated assembly possible.

Compared to through-hole technology (THT), which requires physically securing components with leads and soldering them on the opposite side of the board, SMT streamlines manufacturing.

How SMT Became the Standard

SMT began overtaking THT in the 1980s as manufacturers looked for ways to make products smaller, lighter, and more cost-effective. Early computers, for example, relied on bulky, hand-assembled circuit boards.

SMT changed the game for PCB assembly. It’s faster, more efficient, and allows for compact, high-performance designs:

- Automated placement speeds up production while reducing labor costs.

- Smaller components mean manufacturers can fit more functionality into less space.

- Improved electrical performance means shorter connections that reduce resistance and signal interference.

- Plus, SMT boards handle vibrations better, making them ideal for everything from consumer gadgets to industrial machinery.

Today, SMT is the industry standard. As the demand for miniaturization and efficiency grows, surface mount technology continues to evolve, integrating new materials, techniques, and automation to push the limits of PCB design.

Applications of Surface Mount Technology

SMT is everywhere. Its ability to support high-density, high-speed circuits makes it essential for a range of industries:

Consumer Electronics

Consumer electronics are the most obvious example of applied surface mount technology. Smartphones, laptops, gaming consoles, and smartwatches all rely on SMT to pack powerful processing into compact, lightweight designs.

Without SMT, devices would be bulkier, slower, and more expensive to produce.

Automotive & Industrial Electronics

The automotive and industrial sectors demand extreme reliability, and surface mount technology delivers with its ability to withstand vibrations, heat, and environmental stress:

- Vehicles require sophisticated electronics for engine control, infotainment, safety systems, and autonomous driving features.

- Similarly, industrial automation, robotics, and manufacturing equipment use SMT-based PCBs for high-speed processing and real-time data handling.

Medical Devices

Medical devices are another area where surface mount technology has made a major impact.

Pacemakers, hearing aids, imaging systems, and diagnostic tools require compact, precise, and durable circuit designs. With SMT, manufacturers can produce advanced medical electronics that are both highly functional and small enough to be used inside the human body.

The versatility and efficiency of SMT make it essential for today’s technology-driven world.

Challenges in SMT Assembly

Surface mount technology has revolutionized PCB manufacturing, but it isn’t without challenges.

Accurate Component Placement

SMT parts are significantly smaller than their through-hole counterparts, with some measuring just fractions of a millimeter. At this scale, even a slight misalignment can cause a board to fail. High-speed pick-and-place machines must operate with extreme precision to ensure every component is positioned correctly.

Thermal Management

Reflow soldering, the process that melts the solder paste and secures components, involves exposing the PCB to carefully controlled high temperatures. If heat distribution is uneven or excessive, components can become damaged, leading to performance issues or outright failure. Manufacturers combat this with advanced thermal profiling and heat-resistant materials.

Reliability Testing

With such dense circuit designs, defects can be hard to spot. Manufacturers rely on Automated Optical Inspection (AOI), X-ray testing, and in-circuit testing to catch issues before boards go into final production. These quality control steps ensure SMT-assembled PCBs meet performance and durability standards.

Despite these challenges, SMT remains the most efficient and effective method for assembling modern PCBs. Continuous advancements in machine learning, automation, and material science are helping manufacturers overcome these obstacles and push the boundaries of what’s possible in electronic design.

Future Trends Shaping Surface Mount Technology

The demand for smaller, faster, and more powerful electronics is shaping the next evolution of SMT.

Miniaturization

Miniaturization continues to be a driving force, with components shrinking in size while increasing in complexity. As technology advances, SMT will need to accommodate even denser circuit designs while maintaining high production speeds and low defect rates.

To address this, manufacturers are investing in ultra-precise pick-and-place machines, advanced soldering techniques, and tighter quality control processes to ensure reliability at microscopic scales.

Advanced Materials

New materials are also advancing the possibilities of surface mount technology. Companies are actively experimenting with these materials to push the limits of PCB performance and longevity:

- Solder compounds with improved thermal properties are helping PCBs handle heat more efficiently, reducing failure rates in high-power applications.

- Meanwhile, advanced substrates, such as flexible and high-frequency materials, are opening the door to more specialized applications in fields like wearable tech and 5G infrastructure.

Automation

Automation is another area where SMT is evolving rapidly.

Pick-and-place machines are becoming faster and more precise, and AI-powered inspection systems are improving defect detection rates. Fully automated SMT production lines are on the rise, integrating real-time analytics and machine learning to optimize efficiency and minimize errors. Manufacturers are also using predictive maintenance to reduce downtime and improve overall production quality.

As electronic devices become more powerful and compact, the technology behind their assembly will continue to advance, so expect SMT to remain the foundation of modern PCB manufacturing.

Surface Mount Technology is Evolving—Partner with a Supplier Who’s Keeping Up: Imagineering

Surface mount technology has transformed PCB assembly, making it faster, more efficient, and capable of supporting the ever-growing demands of modern electronics. From consumer devices to industrial automation and medical technology, SMT is the foundation of cutting-edge circuit design. As manufacturers push the limits of miniaturization, advanced materials, and automation, SMT will only become more critical.

If you’re looking for a PCB supplier that stays ahead of these trends, Imagineering is the partner you need.

With expertise in high-quality, precision-driven SMT assembly, we deliver boards built for today’s most demanding applications. Whether you need fast prototyping or large-scale production, we have the capabilities to bring your designs to life.

Contact Imagineering today and turn your vision into reality.