Common Reasons for PCB Failure and Circuit Board Repair

Printed circuit boards are part of your life, whether you know it or not. Whether it’s your laptop, your phone, or your LED-dazzled beer cozy, when a PCB fails, life can become a frustrating, dysfunctional hellscape. But it doesn’t have to be like this. You can give your broken PCB new life if you know what to look for.

From physical damage to power failure, there are a few reasons a PCB can stop working. Learn how they happen and about your circuit board repair options.

PCB Components

A marvel of modern technology, a printed circuit board (PCBs), manages most electrical devices’ functionality.

These tiny brains can get complicated. There is an infinite array of PCB sizes and configurations since different devices have different electrical needs.

Despite this, just a few core components make up most PCBs, whether in a new laptop, a drone, or a smart refrigerator.

It’s essential to understand some of the vital components before discussing printed circuit board repairs and what can go wrong with a PCB.

- Capacitor. Stores electrical charge for smoother distribution.

- Copper tracing. Copper “tracks” embedded in the board that act like roads for electrical current to pass through.

- Resistor. Mediates the electrical current by “slowing it down.”

- Transistor. Amplifies the electrical charge.

- Battery. Power source.

- LED. Allows current flow in only one direction. Lights up when current is present.

- Switches. Can permit or block current if they are open or closed.

- Inductor. Stores electric current as an electromagnetic field.

- Diode. Controls direction of electrical current.

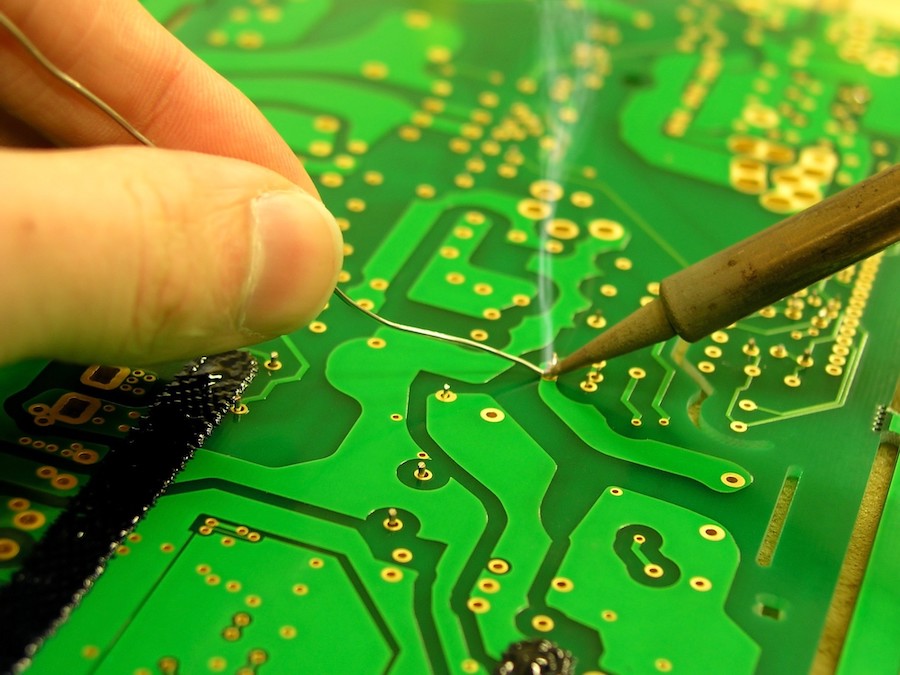

As you might imagine, the surface of a PCB is intricate. With so many vital components packed into a small space, a PCB can resemble a tiny city.

Everything from appliances to cars is going the way of the internet of things (IoT), so PCB demand is only going to increase. Also, PCBs are becoming even smaller and more complex every day.

That leaves a lot of room for malfunctioning. Malfunctioning that can directly affect your quality of life.

If your cherished gadget isn’t working like it used to, it might be a problem with the PCB. Here are the most common printed circuit board repairs to look out for.

Four Common Circuit Board Repair Issues

Many things can go wrong in the life of such a small, sophisticated device.

Lucky for you, what goes wrong in PCBs follows some common trends. The better you understand these trends, the more equipped you will be to make repairs when the inevitable breakdown occurs.

- Physical Damage

That’s right, damage. Not fancy, we know. But with high functionality comes high maintenance, along with a certain degree of fragility.

Anyone going to repair circuit boards is going to check for physical damage first, so why not take a look? Physical damage includes common device “injuries” like:

- Drops

- Impacts

- Heat Damage

- Water Damage

- Dust

- Bugs (yes, bugs)

Physical damage is a dysfunction brought on by external forces. It does not include when something is inherently wrong with the device (we’ll get to shoddy design and cheap components in a minute!)

So take a look under the hood before you do anything drastic. Does any part of your PCB look swollen or damaged by the presence of water?

Does any part look charred, like something overheated and burned?

Is there noticeable rust or corrosion, especially at junctures where wires or components connect.

Is there an excess of dust, or does it look like a tiny bug carcass might be in the way?

Is something broken or cracked? If you were rough with your device, the PCB might have taken the brunt of your lack of finesse!

Even if you are not into PCB repair–DIY-style– it’s good to get the big picture first. You may be surprised at what you find, and what you may be able to fix yourself, easily.

- PCB Component Failure

As components age, they tend to accumulate wear and tear and eventually die out.

One of the first components to suffer this fate is the capacitor. It’s one of the most commonly cited PCB repairs out there.

Like any PCB component, a capacitor does its part to manage the electrical distribution throughout the PCB, helping the device function smoothly.

Many capacitors store electrical charge through an electrolyte paste. As capacitors age, this paste loses its ability to store electrons. As a result, the paste swells, causing the entire capacitor to swell and ultimately stop functioning.

If you take a look at your PCB, notice any bulging components. These are most likely failed capacitors.

Other components can age as well, though they may not be as visibly apparent as capacitors.

- Trace Damage

Damage to the traces usually comes from wear and tear, but can also happen as a result of leaked fluids, which can destroy these vital electrical paths.

Embedded within the circuit board, copper tracings can suffer erosion, causing sickness or death for your PCB.

- Poor Design

…Also, cheap parts. Yes, unfortunately, your PCB might be doomed from the beginning.

Poorly situated components, bad soldering jobs, and insufficient PCB board thickness can all lead to poor connectivity and shoddy performance.

If this is the case, you may simply need to replace it.

While DIY circuit board repair may not be your wheelhouse, it’s important to have reliable help when things go wrong. It’s even more important to get a quality product to begin with.

At Imagineering, Inc, we can assist you with your PCB needs. Our services include manufacturing, prototyping, and design of PCB and PCB components. Our domestic production ensures fast, efficient turnaround time so your project can stay on track.

Printed Circuit Boards: Repair or Replace?

This is the question you’ll need to ask yourself when your PCB starts to act up. Circuit board repair can save a ton of money but can get risky, especially if you don’t have the right knowledge or tools.

Replacing your PCB can be costly and unnecessary if there is just a single component that’s not working right. Save yourself the cost and headaches of PCB repair problems by sourcing your PCBs from the pros. Contact us today to see how we can meet your PCB assembly and fabrication needs.