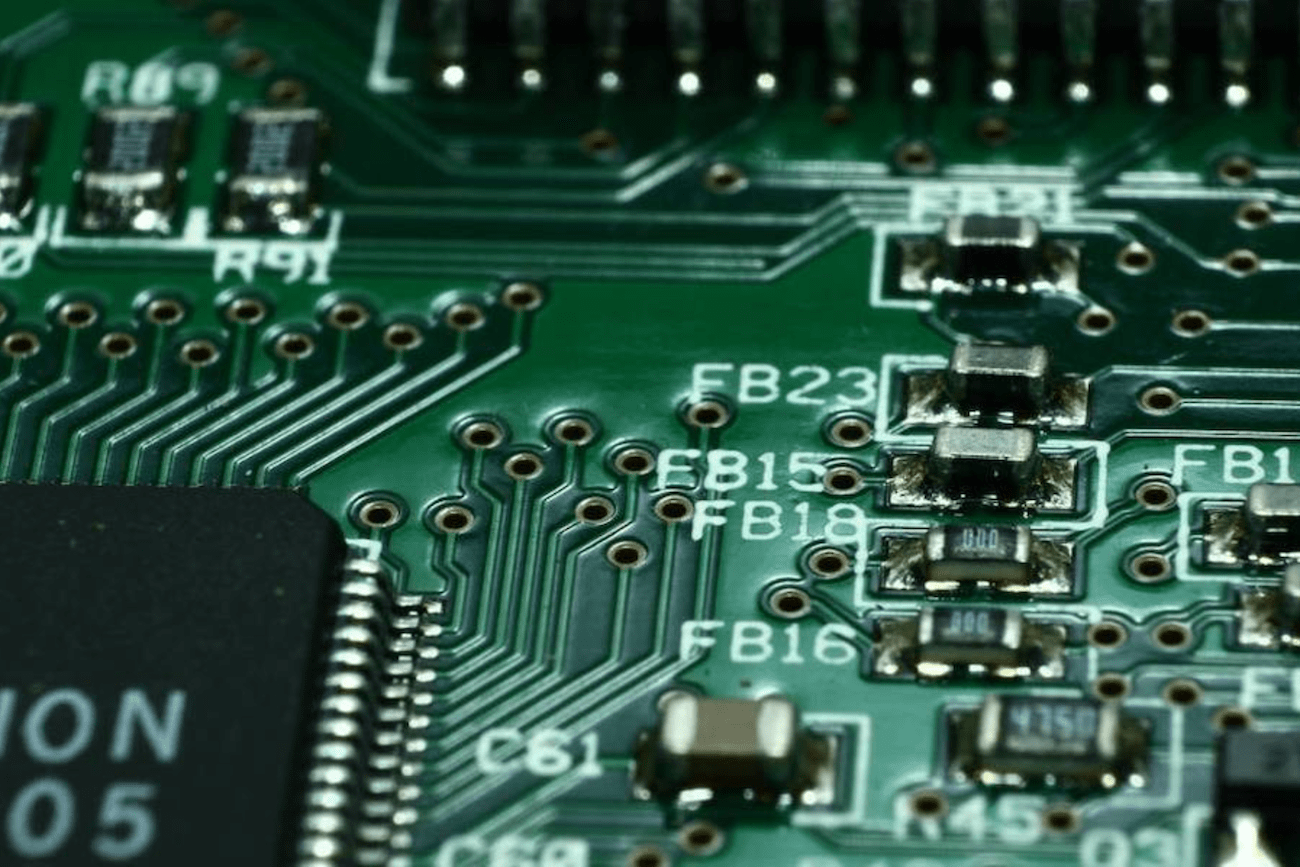

When it comes to manufacturing your printed circuit board, you want to make sure the design is perfect.

Accuracy is paramount when it comes to PCB design, so don’t leave your product—or your client’s satisfaction—to chance. The key to getting it right the first time is making sure the file requirements are in check.

Are you confused about what PCB file requirements you need for manufacturing? Here’s what you need to know to get PCB manufactured today.

What You Need to Know

Despite the global upheaval that is happening in manufacturing right now, PCB manufacturing is on track to grow.

According to the IPC, which sets industry standards for PCB manufacturing, PCB demand continues to outpace supply. For an industry that raked in over $60 billion in 2018, it’s a sign you’re entering a robust field that’s sure to help you profit.

But if you are going to reap the benefits of the competitive field of printed circuit board manufacturing, you should know what the file requirements are so that you can get the best outcomes for your money.

Here are the primary file requirements to consider before you submit your PCB for production.

Bill of Materials (BOM)

The BOM is a breakdown of every part that will go into your PCB. Submit this as a .xls or .csv file. It includes each part’s description and assigned ID number, each component’s manufacturer and part number, and quantity.

For the silkscreen specs, you’ll want to include reference designators. You can also add optional information such as packaging, industrial part numbers, and whether you will be sourcing it yourself.

With so much riding on this investment, it’s essential to ask yourself, “what do I need for manufacturing my PCB?”. While this question is vital, don’t fret, our services include reviewing your specifications to make sure you have what you need before making your PCB a reality.

Gerber Files

Gerber files break down each layer of the PCB. From the silkscreen to the solder paste to the substrate and copper layering, you will need some of the most important specs.

You can generate the Gerber files from your CAD design as though it were going to fabrication. Most PCB manufacturers prefer it in RS-274X format. OCB ++, albeit too large for email, is a viable alternative.

Centroid Data

This file is also known as the “XY Coordinate,” or the “Pick and Play” file. It outlines each component’s placement on the PCB. From the x-y position to the layer to the rotation, the Centroid data is the houses each piece in its functional home.

Net List

A netlist can give a rundown of any discrepancies between the electrical properties you want for your PCB and possible. It’s a reality check that will show all of your electrical connections are valid.

While unnecessary, most PCB manufacturers prefer to have a netlist because, as with everything else, it makes the manufacturing process more efficient and timely.

You may want to submit a netlist in a similar form as your Gerber file, or as an IPC-356.

Mechanical Files

How big does your board need to be? How thick? Where will all of the holes go? You will need to include files that outline the nuts and bolts of your PCB board construction.

The dimensions of your board, where the cutouts, drill holes, and slot placements will be crucial to a functional PCB. Ideally, you’ll have a schematic showing all of this and the copper routes that will connect each component.

Additional PCB Specifications to Include

PCB file requirements need to be precise, so PCB manufacturers like Imagineering, Inc. can make your design a reality. In addition to the requirements listed above, you’ll want to consider the following details.

Copper Weighting

As you know, Copper is the darling conductor of the electronics industry. The copper layer is what makes up the tracings, or conductive tracks of your PCB. If your board is one layer or two layers or more can make a big difference in how that Copper gets distributed.

Surface Specs

How do you want your PCB’s surfaces to be? The solder mask typically comes in one of four traditional colors: green, blue, red, or white. It’s the surface that’s most identifiable when you look at the board.

The silkscreen will give you the ability to print numbers, and even a logo onto your board. We use industry-standard, UV cured inks that are RoHS (restriction of hazardous substances) compliant.

Why Worry About PCB File Requirements?

You want your printed circuit board to be part of a bigger mission of serving your customer’s needs. Simply stated, you want to put out a good product, right?

PCB manufacturing is about precision and functionality, and any flaw throughout the process can mean delay or even death for your company’s mission. Consider the following:

A recent report by the Bureau of Industry and Security gives a trove of data about the PCB manufacturing industry. According to the study (page 35 of this bear), the main reasons for missed opportunities were manufacturers not being able to produce designs. The designs were “beyond the capabilities” of the manufacturer.

Blame much of this loss on unreasonable expectations. However, some of this loss may very well have from a dysfunctional planning and design process. This loss likely could have been avoided through disciplined adherence to file requirements and lock-step guidance throughout the design process.

Your PCB Design and Fabrication Resource

As you can see, PCB file requirements are a crucial component of making a PCB functional. The industrial landscape is shaky these days, and we understand your need to keep the process as efficient and affordable as possible.

You don’t have to go it alone. If you have questions throughout your PCB design‘s critical initial stages, we are here to help. Contact us today for a quote.