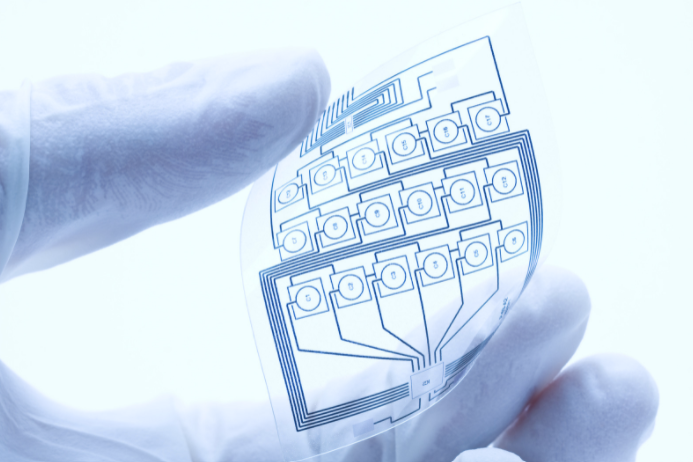

What is a flex PCB, and how does it enhance product design today? A flexible printed circuit board, also called a flexible printed circuit (FPC), has different properties than a rigid circuit board, making it particularly useful for different applications. Unlike many rigid designs, a flex PCB is created out of materials that can bend, giving them improved resistance to vibrations and movement. Thanks to their miniaturized design, they can decrease package weight by up to 75%.

Another key feature comes from minimizing connection points, eliminating interconnection defects that are common with solder joints. They are significantly lighter than rigid circuit boards, and can fit into unusual shapes beyond what is typical for more rigid designs.

With each passing year, the demand for more powerful computing technology grows. However, consumers from all industries expect better performance with smaller weight and size restrictions. This poses a problem: how can I make lighter electronics in increasingly smaller packages? Out of this quandary, the flexible printed circuit board emerged, and its applications have only grown over time.

What is a flex PCB, and what advantages and applications does it offer compared to rigid circuit boards? In this blog, we examine everything you need to know about how it works, its advantages, and its applications in today’s market.

What is a Flex PCB?

The IPC defines a flexible printed circuit as “a patterned arrangement of printed circuitry and components that utilizes flexible base material with or without flexible cover lay.” This definition, while basic, illustrates what you can expect from a flex PCB – a bendable printed circuit that is made of a flexible film.

Flex PCBs, however, have become far more complex over the years as they have been applied to industries across the board. Below, we examine some of the most common types of flexible printed circuit boards being used today.

Single-Sided Flexible Circuits – The most common and simple flex PCBs on the market. They contain a single conductor layer on a flexible dielectric film, and are only printed on one side. They are the most affordable flex PCBs on the market and are relatively easy to produce. These printed circuits are found in most calculators thanks to their simplicity and low weight.

Double-Sided Flexible Circuits – By printing on both sides of a dielectric film connect with plated through holes, double-sided flex PCBs offer enhanced power-handling capabilities and circuit density. While they are popular for their increased power, they are somewhat more expensive to produce than single-sided flex PCBs.

Multi-Layer Flex Circuits – Flexible circuits with three or more layers of conductors. Due to the complexity of their construction, multi-layer flex PCBs are more expensive than their counterparts. They are often used in aerospace and military applications that can justify the cost and capabilities of such a flex circuit.

Rigid-Flex Circuits – A hybrid between standard flex circuits and rigid PCBs, a rigid-flex PCB incorporates a network of rigid circuit boards that typically house components with flexible substrates that connect them together. They are commonly found in commercial electronics such as laptops and smart devices, as well as the military sector that depends on their reliability, strength, and flexibility to ensure consistent performance.

Applications of Flex PCB

Flexible printed circuit boards are suited to a variety of situations where rigid circuit boards

Commercial Electronics – A third of the sales volume for flexible printed circuits come from computer technology – everything from printers, scanners, smart devices, and more. With the market driving for smaller and more advanced handheld technology, flex PCBs are essential for heavy computing power without sacrificing weight restrictions

Automotive – The second largest sector for flex PCBs is in vehicles. The average car looks significantly different from even the beginning of the decade, and their hardware has grown more advanced in turn. As cars begin to include more sensors and electronics for everything from climate control and GPS software to dashboards and rear-view cameras, flex PCBs allow for both space allotments and thermal performance.

Aerospace – Thanks to their remarkable ability to handle the stress of extreme temperatures and vibrations, flex PCBs are uniquely suited for aerospace applications such as satellites. They also can take on unusual shapes that are well suited for spacecraft and substituting connectors that are more prone to failure.

Medical Devices – As medical technology evolves, wearable devices have become a key feature in the past few decades. Flexible printed circuit boards offer greater durability for these devices, as they can mirror shapes found in the body. Hearing aids, vital sensors, and more all use flexible printed circuits to leverage high performance that can stand up to wear and tear.

What is the Advantage to Using a Flex PCB?

Flexible printed circuit boards come with numerous advantages over a rigid PCB. This has made them common in consumer electronics, yet comes with some drawbacks. As a result, rigid and flexible PCBs both have their place, and are often used in conjunction with each other in rigid-flex circuits.

Advantages

- Flexibility allows for extended uses among a variety of products across industries

- Less risk of wire connection failure increases overall reliability

- Reduction in size and weight compared to rigid boards

- Good temperature range makes flex PCBs suitable for harsher environments

- High Circuit Density

Disadvantages

- Higher materials cost than rigid printed circuit boards

- Complex assembly process

- Sensitive to scratching and damage when unprotected

- Requires correct storage procedures

- Difficult to repair

At Imagineering, we specialize in top-quality flexible printed circuits on time at a price that meets your budget and specifications. Contact us today for more information about our services, or request a quote here.