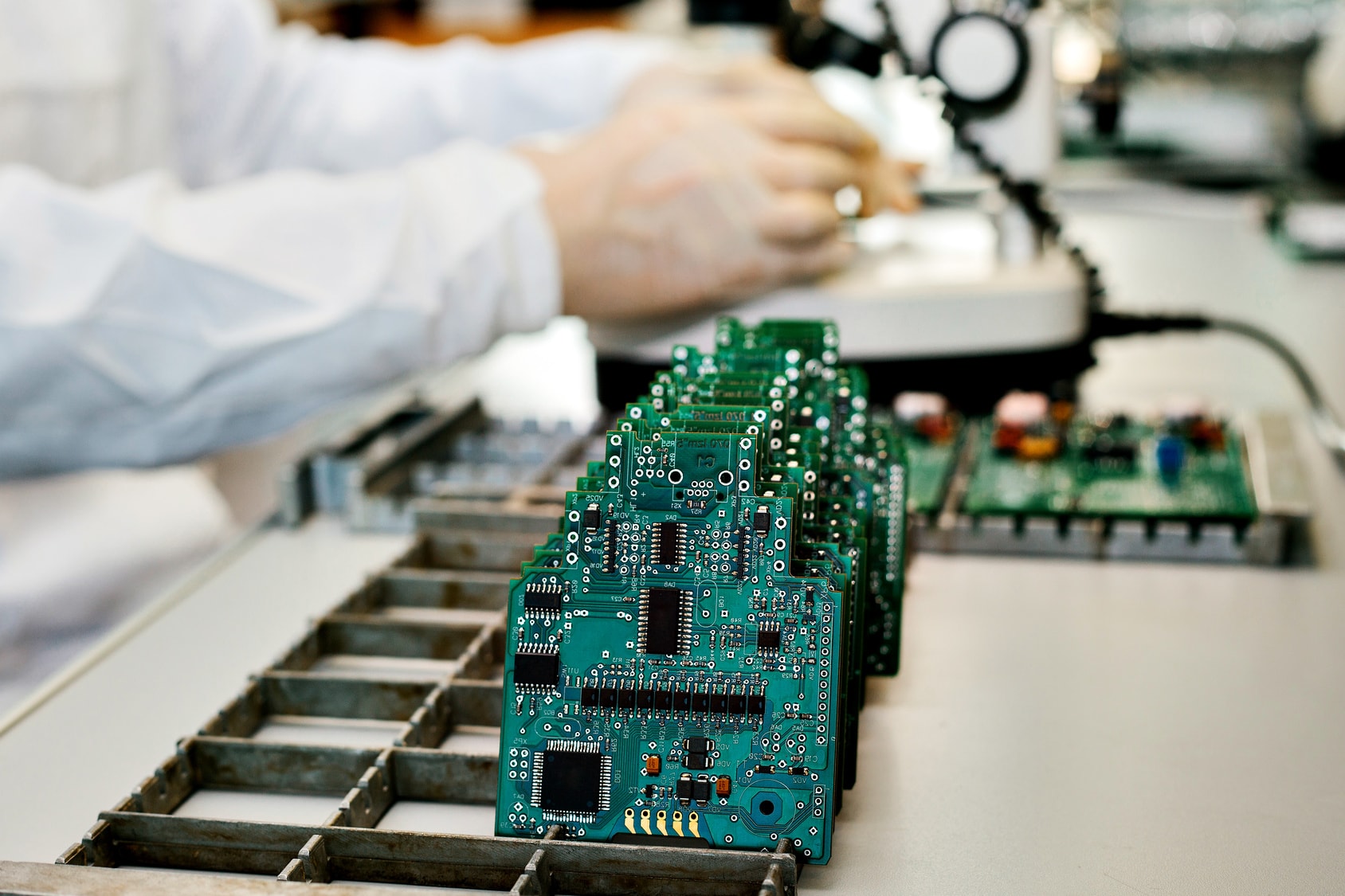

As 2022 draws to a close, it’s time to look ahead to the industry trends, product developments, and sustainable solutions that will influence the market in 2023. In electronics manufacturing, development happens quickly and the printed circuit board industry is no exception. New technologies are implemented every year, enabling companies to achieve high-tech fabrication and affordable functionality.

Ready to jump into 2023 armed with the newest in PCB news? We’ve compiled a short guide detailing the ideas, developments, and up-coming trends that will influence PCB manufacturing in 2023.

What is the Projected Growth for PCB Manufacturing?

Since PCBs are in-demand in nearly every electronic manufacturing sector, it makes sense that the PCB market is forecasted to continue to grow. In fact, according to News Wires, “IndustryARC, in its latest report, predicts that Printed Circuit Board Market size is forecast to reach $72.3 billion by 2026.” This is due, in part, to the increased demand for hybrid and electronic vehicles, which accounts for a significant portion of PCB manufacturing. Additionally, PCBs are included in other automotive features including anti-lock brake systems, ECU systems, and GPS capabilities.

As the PCB market continues to grow, the Asia-Pacific area is forecasted to hold the dominant market share, due to the economies and low labor costs in countries like China, Taiwan, South Korea, and Japan.

What Features Are Most In-Demand?

There are several new features in PCBs that will likely continue to develop and remain in-demand for 2023.

PCB Cameras

The popularity of mobile devices has cemented the expectation that personal electronics will include a camera. PCB cameras are mounted directly onto the circuit board, and include necessary features like a lens, sensor, and aperture. These PCB cameras have undergone massive development in the last few years, and are now used in most hand-held electronics. PCB cameras have both photo and video capabilities, and can produce high-quality images. Due to their compact size, PCB cameras are easy to mount inside smaller electronics. This makes them a popular choice across multiple industries, and they are used in a variety of devices including:

- Smartphones, tablets, and computers.

- Medical equipment, including small “swallow-able” cameras for internal imaging.

- Surveillance technology.

High-Speed PCBs

PCB manufacturers recognize that there’s an increasing need for speed. With the ongoing development of smarter, faster, more efficient devices, PCB manufacturing needs to keep up with the new technologies.

High-speed PCBs are specifically built to minimize signal integrity problems that come from layout issues like track lengths, dielectrics, and EMI. Improved ability to design intricate circuits and tweak layouts has helped develop functional high-speed boards, and it’s likely that high-speed circuitry will continue to be in demand in 2023.

Flexible PCBs

Flexible printed circuit boards are one of the fastest growing sub-groups in PCB manufacturing. These boards are popular due to their compact size and flexibility, and are frequently used in medical devices and other electronics that require a small circuitry unit.

According to Globe News Wire, in 2021 the flexible PCB market was valued at $20.6 billion. This is predicted to grow at a rate of 10.3% from 2022 to 2031, resulting in an estimated value of $55 billion in 2031. With their reliability and adaptability, it’s safe to say that flexible PCBs will make a large impact on the market in 2023.

3D Printed PCBs

3D printing is one of the most popular innovations in PCB manufacturing in recent years, and has revolutionized manufacturing capabilities for PCBs. Using a 3D printer, special conductive inks are used to print the circuitry pattern directly onto the substrate.

Here’s why many companies are adopting 3D printing in PCB manufacturing:

- Since a 3D printer is able to accurately print the circuitry pattern with minimal flaws, this streamlines the fabrication process and reduces the amount of material waste that’s typically produced during standard manufacturing

- The accuracy of 3D printing enables other innovations, like high-speed and flexible PCBs. For example, a 3D printer can handle the intricate circuitry used in a high-speed board. This reduces human error and produces more consistent results.

- 3D printed PCBs are available in a wider variety of materials, which allows manufacturers to choose more environmentally friendly options.

What is the Environmental Impact of PCBs?

Electronics manufacturing in general is a large contributor to landfill waste. According to Innovation News Network, “Estimates from the WEEE Forum suggest that in 2021, there were 57.4 million tons of electronic waste – greater than the weight of the Great Wall of China – the heaviest artificial object on Earth.” What’s more, electronic waste has seen a 21% increase since 2014.

Personal / hand-held electronics, which are typically made using PCBs, make up a large percentage of the products that end up in landfills. Although most PCBs adhere to strict safety regulations before hitting the market, many still contain harmful heavy metals and chemicals. When PCBs aren’t properly recycled, these elements soak into the soil and will develop into a health hazard for people and animals.

What are Sustainable Solutions for PCB Manufacturing?

As PCB manufacturing continues to develop, the industry is adopting more environmentally friendly manufacturing practices in hopes of curbing non-biodegradable waste. One of the most exciting new developments is the production of paper PCBs. These new paper-based printed circuit boards are made using conductive inks printed onto a paper substrate. While these boards are still under development, 2023 will likely usher in a new era of biodegradable circuit boards.

Recycling is another sustainable practice that’s becoming more popular for circuit boards that have reached the end of their life. Trace amounts of limited-resource elements, like copper and tin, are used in circuit board manufacturing and these can be extracted, melted down, and reused for other devices. Additionally, increased use of precise 3D printing technology has limited the amount of excess raw materials wasted during the manufacturing process.

Planning Ahead for a Successful Future by Partnering with Imagineering

While no one has a crystal ball, we can still make informed predictions about the future of electronics manufacturing. One thing that’s certain is manufacturers will continue to favor innovative, high-quality, cost-effective circuit boards that are hand designed to fit their unique needs. That’s why electronics manufacturers continue to partner with Imagineering.

Imagineering is a printed circuit board manufacturing company dedicated to providing customers with aero-space quality circuitry at budget-friendly prices. We believe our customers shouldn’t need to break the bank to afford high-quality circuit boards. Wondering what sets us apart from the competition?

- Fast Turnaround Times: we offer same-day circuit board prototypes and production in as few as 5-7 days.

- End-to-End Customer Support: Imagineering is a US-based company, and we offer customer support throughout the entire manufacturing process. From design to delivery, we’ve got your back.

- Affordable Prices: we manufacture medical and aero-space quality circuit boards at affordable price points. By partnering with offshore manufacturing facilities, we utilize our global network to offer our clients affordable products designed by experts.

- Certification You Can Trust: Imagineering is certified by some of the leading authorities in quality standards for electronics. We are proud to be AS9100D/ISO9001:2015 certified, WEEE certified, RoHS certified and a member of the IPC.

Are you ready to embrace innovation in 2023? Contact Imagineering to receive a quote and learn more about our services.