Imagineering Inc. is a company that takes pride in making high-quality and certified printed circuit boards (PCB). The company accomplishes this by following a two-pronged approach to manufacturing. This involves employing overseas as well as domestic sources of manufacturing. The reason for this is simple. Imagineering can leverage the cost savings associated with offshore production, but at the same time, keep a close eye on quality control.

However, manufacturing is not done completely abroad. The company has state-of-the-art facilities at home that work in tandem with offshore facilities. This hybrid approach has worked well for Imagineering, which allows them to remain competitive by providing high-quality printed circuit boards at aggressive prices. The following is a brief look at the advantages of combining offshore and domestic PCB manufacturing.

- Reduced labor cost

- Quality control

- Reduced raw material cost

- Handle scaling more efficiently

- Accessibility of local talent

Labor Cost

Labor cost is one of the main reasons why offshore manufacturing took off in a big way. The idea became so popular that, many manufacturers were willing to ignore most problems, to take advantage of the resultant cost savings. However, in due course, offshore manufacturing destinations improved their game, which made the whole concept even more enticing. Today it is virtually unthinkable to be a part of almost any business without including offshore talent as well. Imagineering understands this, but at the same time in a high-stakes world of PCB manufacturing; the company realized it needed to retain some of the work, to keep an eye on things such as quality.

Quality Control

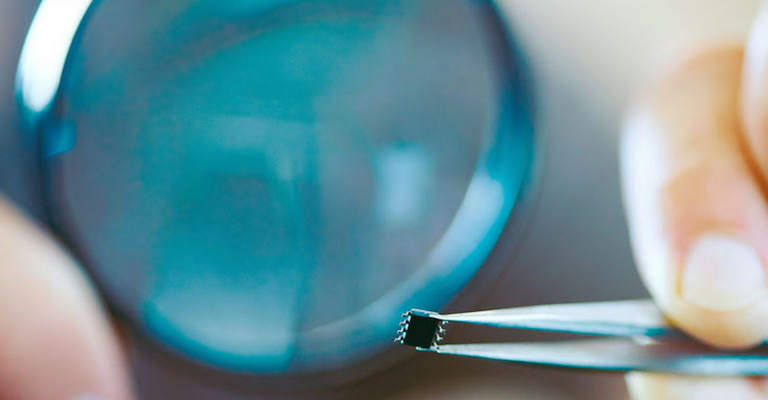

One of the most important aspects of manufacturing, quality control is much easier and faster to accomplish when done domestically. Cheap manufacturing means nothing if quality levels are not reached. This is why Imagineering makes sure to test all its products in-house before sending it out to the customer.

Raw Materials

Nothing can be done in manufacturing without proper raw materials. This is a trump card of many offshore destinations. Countries that offer this kind of service is either at or close to places that provide the necessary materials to make things, sometimes at a much lower cost.

Scaling Efficiently

For any business involved in manufacturing, it needs to be able to handle an increase in demand. Scalability can only be achieved when the manufacturer has flexible resources at hand. However, flexibility is costly for a domestic manufacturer to handle alone. With the help of offshore facilities, Imagineering is capable of handling high demand at short notice.

Local Talent Pool

Access to regional talent is not only about ordinary talent, although this is a major benefit. It is also about getting access to highly specialized talent operating highly specialized equipment. This is a huge plus for any business that may be working on, say, a prototype or something that only needs to be made occasionally.

Remaining Nimble

A company such as Imagineering can stay agile because of its offshore manufacturing. Imagineering achieves this without losing quality control since this is done in the U.S. This is done by testing products and also making sure all compliances are met to the company’s standards. Any company that sees itself as a serious player in manufacturing will have to take a closer look at offshore manufacturing at some point in time. In most cases, the benefits outweigh the downsides, and even the downsides are usually the results of poor management or communication. Once due diligence is done, businesses can build a path towards success.