Full Turnkey PCB Assembly

In a fiercely competitive market, you can use several methods to ensure that your company remains agile and relevant in the manufacturing industry. An ideal way to do that is by selecting full turnkey PCB assembly services for your upcoming project. With full turnkey PCB assembly services, you will have everything you need to get the PCB product to market faster without increasing the cost. The contract manufacturer will handle the whole process including assembly, manufacturing, testing, ordering the components and final shipment. With such stressors out of the way, you can focus on PCB design, delivering products timely and enhancing other business processes. In addition, this process eradicates the communication challenges that come with dealing with several suppliers. This single-source approach saves you time and money, while ensuring more consistent and reliable results.

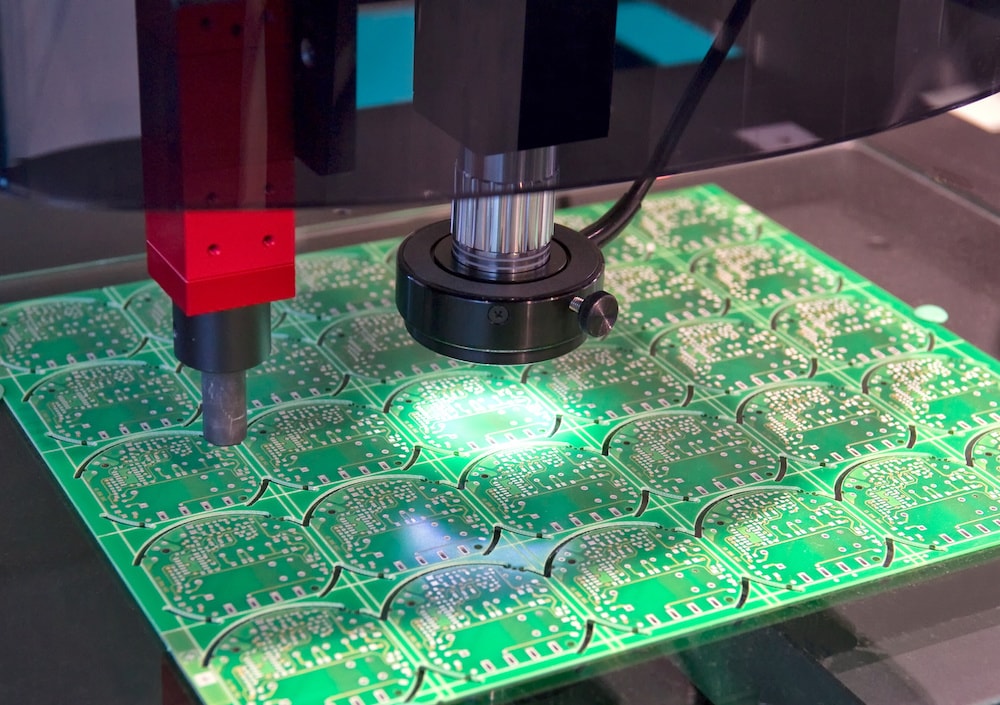

This is what we do for our customers here at Imagineering. We offer full turnkey PCB assembly and are capable of assembling QFN, Micro-BGA, BGA and other leadless package parts. We keep bare boards, components, and assembly labor under one roof so that our team can provide aerospace quality at standard prices. This also allows us to offer low-volume to mid-volume production runs. We rely on the highest-caliber equipment for our turnkey assembly services and ensure the highest quality through our full 3D automated optical inspection. This helps us eliminate all the sources of defects.

Full turnkey services help avoid risk, move quickly to meet market demands, and keep a low overhead. While many customers choose to take advantage of full turnkey PCB assembly service contract manufacturers take care of component sourcing and assembly, it’s also important to recognize that some customers may prefer to provide some or all of their own parts. That’s why many companies also offer consigned and partial consigned PCB assembly services.

Consignment PCB Assembly

Manufacturer’s expertise. Customer’s parts. The result is a custom PCB assembly that meets the customer’s exact specifications. With consignment assembly services, a contract manufacturer will work closely with the customer’s in-house supply chain to get PCBs assembled and to market quickly. Once the manufacturer receives the parts and components required for the circuit boards, they handle the assembly.

This solution is ideal for customers that have their own components for the project. They simply send the kit to the contract manufacturer that offers consignment assembly services and can get started on it immediately. Manufacturers should have a thorough inventory process that ensures all customer’s parts have arrived before the start of the assembly.

If your business is looking for PCB consignment services, Imagineering offers:

- An in-depth inventory process so that we can ensure that all the parts are available prior to assembly. We go the extra mile and examine every kit for completion.

- Storage for parts in our humidity and temperature-controlled cabinets.

- Storage and warehousing services to ensure that customer’s products are available for their upcoming project.

In addition, here at Imagineering we use automated equipment to perform all our assembly processes. These processes include automated optical inspection, jet printing, component placement, and soldering.