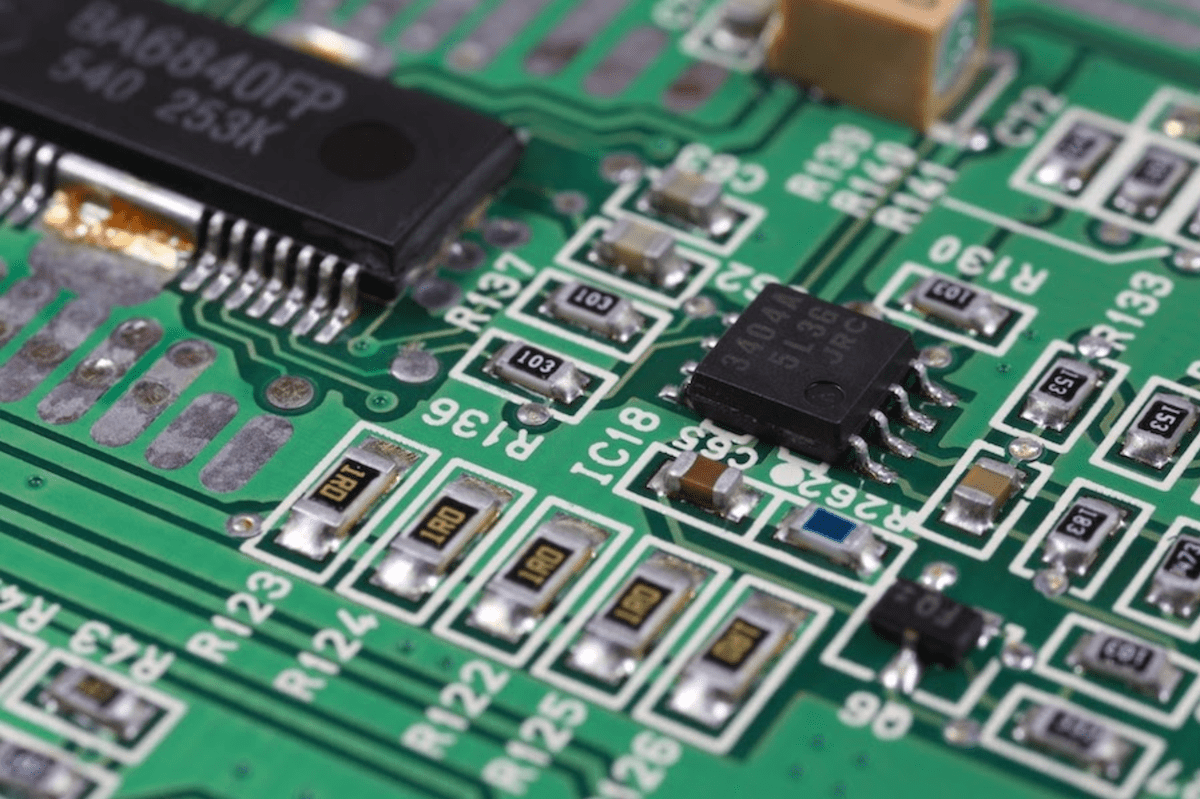

For many years, US electronics manufacturers have relied on imported printed circuit boards (PCBs) for their products. Few of them are aware that PCBs can be assembled, prototyped, and fabricated at affordable prices in the United States.

Manufacturers turning to local suppliers of PCBs should know a bit about the market. They should also have some idea about what PCB prototyping involves to ensure they are getting the service and the PCBs they want.

Knowing about the different processes involved with PCBs will lead you to understand that PCB prototyping and production go hand in hand.

PBC Assembly

Imagineering Inc.’s assembly services handles all PCB assembly needs, offering a 24 hour turnaround from the U.S. headquarters or offshore facilities. You can rest assured that you’ll receive the highest quality printed circuit boards at super-fast turnaround times to either Class II or Class III inspection standards.

PBC Fabrication

PCB Prototyping is considered small volume batch runs before large volume production. Prototyping is used to discover flaws in the design before making the large volume productions. Our fabrication capabilities at our US headquarters in Elk Grove, Illinois, boast DFM (Design for Manufacturing) status. We test all PCBs fabricated (produced) for DFM compliance.

Compliance testing is one way to discover potential design flaws or manufacturing problems, and this is where we enter the realm of prototyping.

What Are the Benefits of PCB Prototyping?

Before going into full production, you need to be sure that your PCB functions as it should. PCB Prototyping is essential to ensure PCBs measure up to your precise specifications, but it can also prevent costly errors. Imagine the disaster of discovering PCB failure after full production; it would entail costs that could have been avoided.

PCBs are an integral part of many electronic devices. Prototype PCBs are useful early in the design process to test functions and ensure that they are working fine. Sometimes, engineers order multiple runs of prototypes if corrections to earlier designs have been made, and retesting is required.

Surface-mount technology (SMT) means that circuit boards don’t have to be drilled before assembly. The advantage of SMT PCBs includes smaller PCBs, but more importantly, SMT allows the possibility of using EDA, or electronic design automation software. EDA helps to produce superior designs and speed up the prototyping process, with its in-built simulated tests and checks.

We pride ourselves on our design services. All we need from you are your specifications. Getting your specs to us is as easy as filling in a form for a rapid response, comprehensive quote on our site.

SMT can be combined with through-hole construction, if necessary, but customers should be aware that production set-up will be slightly slower since all holes have to be drilled before assembly.

Your Specifications and Our Capabilities

You’ll find three quote types on our Get a Quote page:

- Board (or fabrication) quote

- Assembly quote

- Quotes for advertised special offers

Board Quotes

For Board quotes, we offer multi-layer, rigid, and flexible PCBs. We can also produce boards on niche substrates such as Nelco, Arlon, aluminum core, and many others.

Aside from our any quantity option, we offer five different thicknesses as standard options and up to 14 different layers per board. You specify your dimensions.

You can choose from the following materials: 130Tg FR4, 170Tg FR4, or CEM1. Contact us if you require unique materials. Copper weights range from 1 to 4g.

Finish plating can be leaded solder, or any following RoHS-compliant finishes: lead-free solder, immersion gold, immersion silver, white tin, or OSP (organic solderability preservative). Minimum trace spacing ranges are from 0.005–0.008″. Testing is optional.

SMD (surface mount device) components can be on the top, bottom, or both sides. You can also specify the SMD pitch and the number of pads. If through-hole punching is selected, specify the smallest hole diameter (0.010–0.015, or greater) and the approximate number of holes.

Similarly, masks can be on the top, bottom, or sides and are available in green, black, white, blue, and red.

Assembly Quotes

For assembly quotes, you can specify the number of unique parts, the total number of placements and through-hole placements, and whether you want double-sided assembly. You can also check the BGA/QFN (ball grid array/quad flat no-leads) parts box and the AS9100 compliance box.

Advertised Specials

Watch out for our advertised specials, since these might cover most of your basic specifications and you could get an even better deal from us than you usually do.

Standards Compliance

A massive clue about the reliability of your PCB manufacturer is its compliance with national and international industry standards. Standards apply to individual PCB components, the production process, and testing procedures. Both PCB prototypes and regular, or standard, PCB production need to comply with various standards.

If you incorporate non-compliant PCB components in your manufactured products, your products will likely face export restrictions. Since standards are updated as technology evolves, you need a PCB prototyping producer like Imagineering Inc. to keep abreast of these regulations for you and advise you and act accordingly. The recast RoHS 2 Directive 2011/65/EU, published in July 2011, is a case in point.

We are AS9100D Certified and ITAR compliant. In addition, we work to IPC-A-600 F (Class 2 standard) as a minimum, and can also produce PCB prototypes and orders to Class 3 inspection level.

Technical Expertise

When dealing with printed circuit board manufacturers, you need to be confident in their technical expertise and ability to build prototypes and produce PCBs for you to your exacting standards. If your PCB supplier’s technical expertise does not convince you, the simple solution is to talk to us.

We’ve kept abreast of technological advancements in this field in the 26 years we’ve been in business. That’s why we were able to take over 9,000 prototypes to production in the last twelve months alone.

We understand the design complexities involved in getting your prototype and standard PCBs up-to-scratch right away. And we’re capable of doing it in record time.

Get PCB Prototyping with Imagineering

Watch our video explaining how you can get a full turnkey quotation from us online in minutes by uploading your bill of materials and necessary information concerning board size, material, type of finish. You will receive an email from us within minutes that gives you a quotation breaking down component costs, building the board, and fabricating the board. Our quotes will cover whatever the customer wants, whether prototype quantities or volume quantities.

Imagineering Inc. focuses on high-mixing all volumes. We’ve always followed a customer-driven model of business. That’s a fancy way of saying that we give our customers what they want, and, if necessary, throw in a bit of professional advice too.

Get in touch with us for all your PCB prototyping needs. We’ll be happy to meet your specs!