The printed electronics market is quickly finding new commercial opportunities. Conductive inks are evolving to meet these needs.

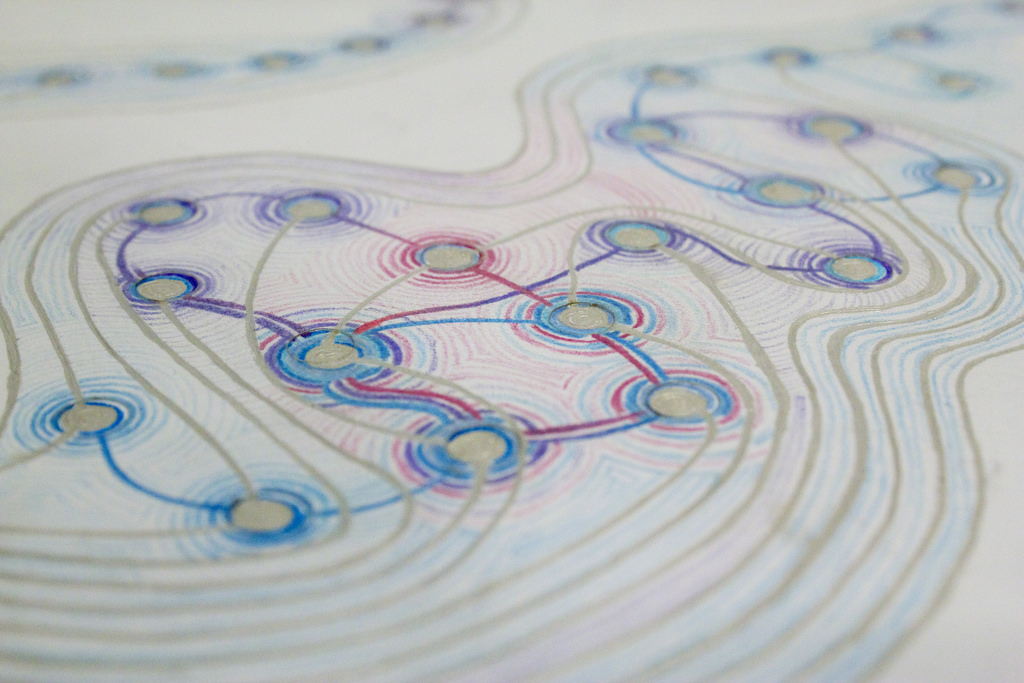

Conductive ink is applied to an object or substrate as a conduit to conduct electricity. These inks are one of the key material ingredients in the fabrication of printed electronics. As the market and demand for printed electronics grow, so will the market for conductive inks.

The demand for advanced technology and increased quality of conductive inks is driven by a growing demand for smaller compact devices in the semiconductor industry, where the right conductive ink in the right application, can help replace bulky and heavier applications. Conductive inks and pastes may also be layered upon a substrate to reduce weight and thickness, but increase the flexibility of the finished product.

Conductive inks are a $2 billion market. They are commonly classified as silver conductive inks, copper inductive inks, conductive polymers, conductive nanotube ink, graphene or carbon ink, and others. Silver conductive inks were most demanded in 2016 due to their large-scale applications in energy, medical, and the consumer electronics industry.

When a larger industry demands goods and products requiring printable electronics with minimal weight and size the proper ink makes a difference. The right ink helps reduce weight and size while affording the desired performance of the printed electronics. This helps drive the demand for performance ink. The solar industry is one of the larger volume users of conductive inks and pastes as the installation and overall demand, on a worldwide basis, is on the rise.

Ink characteristics and properties are advancing to add to new and exciting electronic products. The Dupont Corporation recently introduced a new generation of stretchable electronic ink and films for “smart” clothing. The materials are being unveiled concurrently with a new brand identity – DuPont™ Intexar™ smart clothing technology.

Intexar™ transforms ordinary fabrics into active, connected, intelligent garments that provide critical biometric data including heart rate, breathing rate, form awareness and muscle tension. Intexar™ offers superior stretch and comfort and is easily integrated into garments to make smart clothing. This is a remarkable achievement in the use of electronic inks and foreshadows the many technology products that are possible.

Conductive inks are also developed in response to information technology and industries that continue to rely heavily on electronic advancements. For example, electronic wearable devices, IoT hardware and sensing equipment and components, smart packaging and emergent technology advances in automotive, aerospace, and defense – are all on the rise. The growth in such electronics requires newer and better conductive inks to meet specifications.

Each day new products are released that the printed circuit board industry can benefit from in time. There’s a lesson to be learned in innovation and the adoption of new technology. When innovative technology such as IoT sensor capability, complex RFID devices, and printable electronics such as smart clothing are growing, the PCB manufacturing industry stands to benefit.