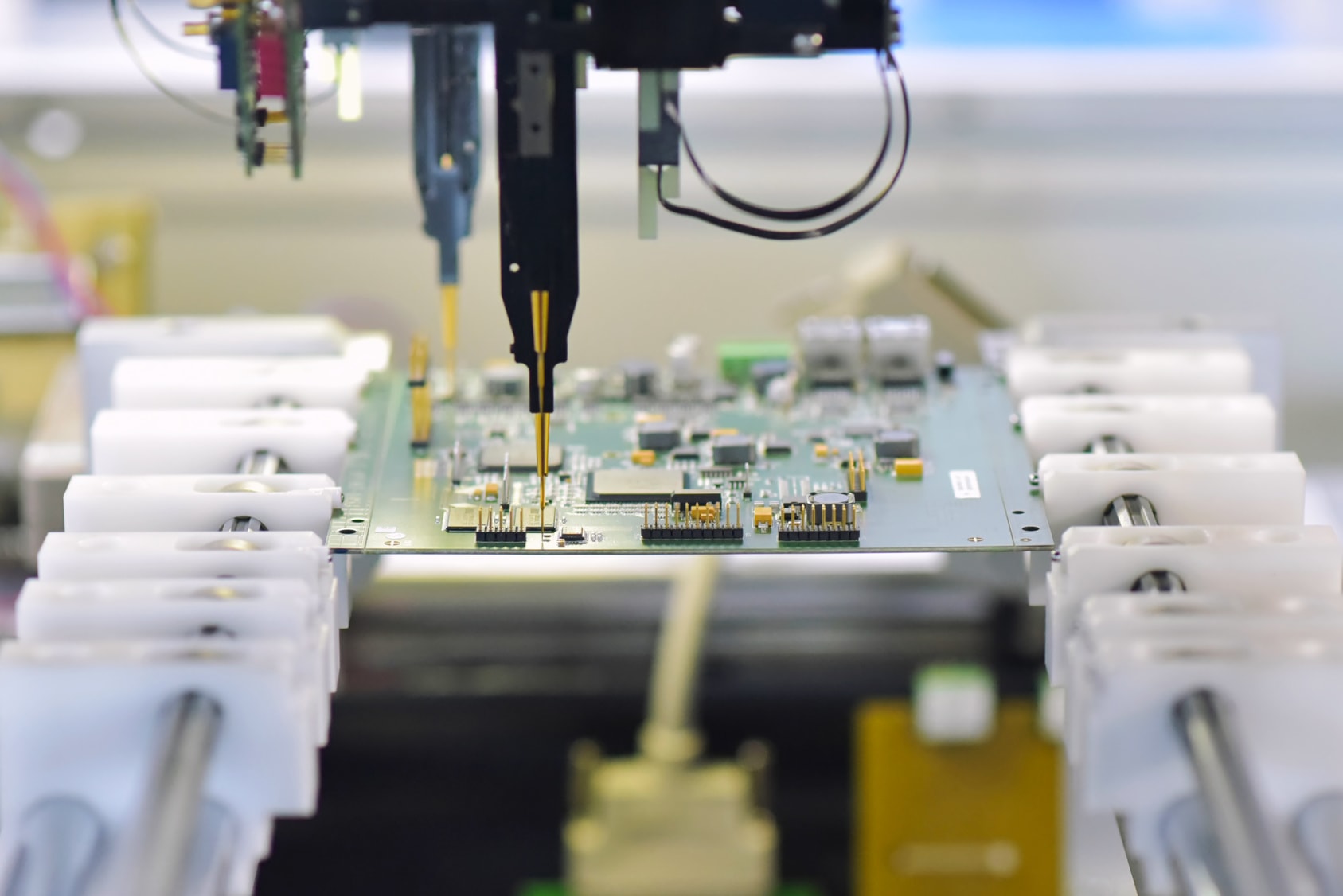

Aerospace PCB assembly requires greater control and no errors. Each stage of the assembly process is carefully designed to deliver a flawlessly functioning board. With continued electronics advancements, machinery for manufacturing PCBs is improving – and the industry itself is more exciting than ever. Using state-of-the-art equipment and assembly services, contract manufacturers can create, test, and meet demanding specifications for the highest quality of deliverables.

High-Caliber Equipment for Cutting-Edge PCB Assembly

Aerospace-quality PCB assembly is only possible with technologically advanced equipment. Whether you need small- or medium-to-large-volume production, you need to be able to trust your assembly professional’s turnaround time. That’s one reason the best equipment is important. You can depend on your job to be delivered on-time and within budget because there won’t be delays due to equipment failures.

Every PCB project should be managed by a knowledgeable team of professionals. A contract manufacturer should invest in the equipment needed to complete demanding specs and in employee training and proper equipment maintenance. High-caliber equipment run by highly trained employees makes it all possible.

Dynamic Production, Professional Precision

One of the best solutions to the complexities of PCB manufacturing is a powerful inventory management system. It uses innovative feeder technology and automatic storage with full material tracking and paperless operator guidance. This ensures the correct material is loaded into the machines with minimal human effort.

Imagineering Gets the Job Done Right. Every Time

Here at Imagineering, our PCB manufacturing processes are compliant with some of the world’s most stringent standards. Our equipment can handle a wide range of components with uncompromising production quality, total stock accuracy and complete traceability down to individual PCB serial number. This equipment allows us to switch effortlessly from full volume to batch size one.

We are able to deliver new levels of precision and flexibility in a faster, smaller and smarter format. Some of our system features include:

- Fully automated board train functionality – significantly increases throughput with simultaneous loading and unloading of multiple boards.

- Next-generation precision – provides extremely precise on-the-fly positioning and inspection for any type of miniaturized or specialized component.

- Electrical verification is performed on the utility wagon’s test surface. It helps reduce wear on the contact area while allowing testing of new package types.

The Importance of Powerful Software

Our team works with a powerful software suite that ensures that all employees, from an engineer to stock manager or machine operator, have access to accurate and up-to-date information. This allows us to bring quality and reliable PCBs to our customers, no matter whether you are a professional engineer or an aspiring maker.

Equipment Maintenance

Successful aerospace PCB assembly process doesn’t only rely on equipment alone, but also on its maintenance. We replace equipment parts based on data to get more efficient part usage and identify problems before they arise and thus reduce unscheduled downtime.

If you’ve been placing orders with multiple suppliers in other countries and have managed the complications of foreign/U.S. Customs requirements, Imagineering’s reliable one-stop-shopping is the perfect time-saving solution for you.Let us give you aerospace quality at standard prices. When you’re ready for best-in-class service, call (847) 806-0003 or get a quote.