If you have a vision for a product you really believe in, your decision on where to buy PCB components can be make-or-break. Whether you’re sourcing for mass production or a one-off prototype, the choices you make at this stage can define the performance, durability, and long-term viability of your product.

We want to give you a solid foundation, so in this guide, we’ll cover:

- The different types of PCB components and what they do.

- Technical specs you need to get right the first time.

What to look for in a supplier, and what to avoid. - Smarter sourcing strategies that save time, money, and frustration.

Let’s start by making sure you understand what exactly you’re buying.

Understanding the Types of PCB Components

Before you can truly understand where to buy PCB components, you first have to know what you’re buying. Not all components are created equal, and knowing the difference can save you from design headaches and assembly disasters. Here’s how to understand the types of PCB components.

Three Main Categories of Components

Most parts fall into one of these three buckets:

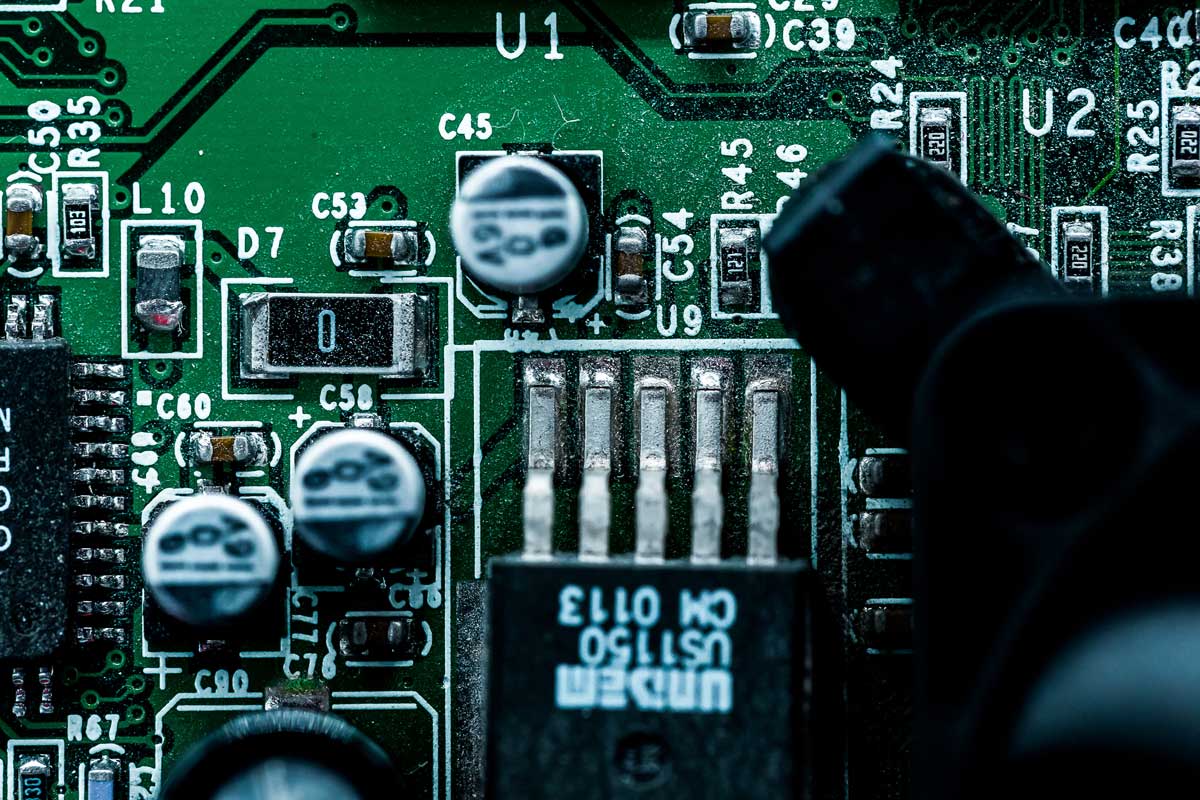

- Passive Components: These include resistors, capacitors, and inductors. They don’t amplify or switch signals, but they’re foundational for shaping, filtering, or storing energy.

- Active Components: Transistors, diodes, and integrated circuits (ICs). These are the brains and muscle of your circuit. They control current flow, execute logic, and process signals.

- Electromechanical Components: Think connectors, switches, relays. These create a physical interaction between your board and the outside world.

Before you finally decide on where to buy PCB components, you also need to consider how they’ll attach to the board.

Surface-Mount vs. Through-Hole

There are two main ways to attach components to a board, and your decision between them will definitely affect your choices.

- Surface-Mount (SMT): Smaller, faster to assemble, but tougher to work with by hand.

- Through-Hole: Easier for prototyping and more durable in high-stress environments.

To put it simply, surface-mount is sleek and speedy for machines; through-hole is bulky but forgiving for human hands.

Finally, be wary of old parts. Just because a component worked ten years ago doesn’t mean it’s available or supported today.

Bottom line: Understanding what you’re working with is step one. Sloppy sourcing starts here, so don’t skip it.

3 Technical Factors to Consider Before You Buy

Specs matter. Choosing the wrong part (even one resistor out of spec) can tank a build or send your budget off a cliff. Before you can choose where to buy PCB components, you’ll need to lay the groundwork.

1. Electrical Ratings: Get It Right the First Time

Start with the fundamentals: every component must fit your circuit’s electrical demands. That includes not just what the part can handle on paper, but what it will face in real-world conditions.

A few of the most important ratings to verify:

- Voltage rating – Always choose components that exceed your expected voltage by at least 20%.

- Current capacity – Look for continuous current limits, not just peak tolerances.

- Tolerance – Don’t assume “close enough” is good enough. In analog and RF applications, tight tolerances can make or break functionality.

- Power rating – Make sure resistors, inductors, and other parts can safely dissipate the heat they generate.

Underrated components can pass early tests, only to fail under sustained load. And when that happens, it’s rarely just the one part that needs replacing.

2. Heat and Durability: Design for the Real World

Components don’t live in ideal conditions. If your board generates heat, moves, or sits outdoors, your parts need to withstand more than just average wear.

For thermal considerations, check the datasheet’s thermal resistance values (often listed as RθJA or RθJC). You’ll want components that can dissipate heat effectively, especially in power supply sections or near processors.

Strategies for thermal and mechanical resilience include:

- Spacing out high-draw components.

- Using thermal vias or exposed copper areas to aid heat dissipation.

- Choosing industrial-grade parts for applications exposed to vibration, impact, or temperature swings.

Consumer-grade parts might be cheaper, but if your application is demanding, you’ll pay for that decision later.

3. Compliance and Lifecycle: Don’t Get Caught Off Guard

Regulatory and lifecycle issues can sneak up on you if you’re not careful. Your components need to work tomorrow as well as they work today.

Before you commit to any component:

- Confirm compliance with RoHS, REACH, and other applicable standards.

- Avoid parts labeled EOL (End-of-Life) or NRND (Not Recommended for New Designs).

- Use tools like Octopart or manufacturer sites to check availability and supply chain stability.

Nothing derails a production run faster than finding out your main IC was discontinued last month.

Bottom line: Technical due diligence isn’t just a best practice, but the cost of admission. Lock in components that meet your design, match your layout, hold up in the field, and won’t vanish the moment you scale.

Where to Buy PCB Components and How to Source Them Effectively

Finding the right supplier is as important as finding the right part. You want reliability, traceability, and consistent stock, not just the lowest price.

Choosing the Right Supplier: What to Look For (and What to Avoid)

The choice of where to buy PCB components should be narrowed down to vendors who:

- Provide complete, accurate datasheets and lifecycle information.

- Maintain strong stock visibility with clear lead times.

- Back their inventory with authenticity guarantees and return policies.

Avoid anonymous listings, unclear branding, or “too good to be true” pricing. Counterfeits and surplus parts can work fine in test builds… until they don’t. And if they fail in the field, you’ll be the one answering for it.

Building a Smarter Sourcing Process: Tools, Habits, and Long-Term Strategy

Once you’ve decided where to buy PCB components, make sourcing more efficient with these habits:

- Maintain a detailed bill of materials (BOM) that includes preferred part numbers, alternates, and sourcing notes.

- Use tools like Octopart, FindChips, or TrustedParts to track real-time pricing, availability, and cross-referenced equivalents.

- If you’re ordering regularly, develop a relationship with your supplier. Dedicated reps can help you stay ahead of shortages and even flag parts nearing end-of-life.

For small operations or hobbyists, low-volume distributors and curated kits can help you avoid bulk minimums. Just don’t commit too early. Wait until your design is locked before buying in volume.

Whether you’re scaling a product or building a one-off prototype, smart sourcing is about more than getting parts in hand. It’s about creating a process that supports accuracy, traceability, and growth.

Choose a PCB Manufacturer that Understands Component Sourcing: Imagineering

From component types and technical specs to sourcing strategies and supplier red flags, buying PCB components has to go beyond availability. You need a reliable foundation for whatever you’re creating. Whether you’re an engineer scaling production or a builder refining your prototype, the details covered here can help you avoid costly mistakes and move forward with confidence.

At Imagineering, we don’t just manufacture PCBs. We’ve succeeded thanks to our deep commitment to everything from the design of the board to component sourcing to assembly. If you’ve got questions we didn’t answer in this blog, or if you’re interested in how we can make your vision a reality, reach out to us today.