The global PCB market was worth over $78 billion in 2021, which analysts expect to reach $128 billion by 2030. This growth is because most modern electronic devices contain a printed circuit board (PCB), reducing the product’s size and making it more cost-effective. The rapid evolution of this industry means there are many trends for PCBs in 2023, including the following:

- Increased Use of Flexible PCBs

- Push for Better Customer Service

- Integration of IoT and AI Technologies

- 3D Printing of PCBs

Increased Use of Flexible PCBs

The increased use of flexible PCBs is a driving factor behind the rapid growth in this market, especially for mobile devices like laptops, smartphones, and tablets. Wearable technology is also a growing application for these PCBs.

Other names, such as flex circuits, flex circuit boards, flexible printed circuits, and flex PCBs, also known a flexible PCB. They use a flexible substrate, unlike traditional PCBs that use a rigid substrate. This flexibility allows manufacturers to bend the PCB into the desired shape during product assembly.

Flexible PCBs are becoming widespread due to their many advantages over rigid PCBs. For example, they can reduce the size of an electronic device because manufacturers can easily fold these PCBs into a space-conserving shape, which is one of their most important benefits.

Flexible PCBs also reduce the risk of damage during assembly because they’re less likely to be damaged. In addition, their flexibility gives designers greater freedom since flexible PCBs can have more layers than rigid PCBs.

The most popular applications for flexible PCBs include the following:

- Avionics

- Airbag systems

- Antilock brakes

- Bar code equipment

- Battery packs

- Cameras

- Fuel pumps

- Motion systems

- Satellites

- Semiconductor devices

- Ultrasound probes

The disadvantages of making flexible PCBs generally relate to the greater variety of materials used in their construction, as manufacturers must consider many factors when selecting the materials to combine.

For example, differences in the coefficient of thermal expansion (CTE) can cause laminated materials to separate when the temperature changes. Manufacturers must therefore implement a reinforcing board to align the layers during lamination accurately.

Push for Better Customer Service

The COVID-19 pandemic that began in 2020 pushed consumers to transition to a virtual buying environment, resulting in a greater need for good customer service. Modern solutions for customer service are becoming a routine expectation for PCB buyers, who may have experienced challenges with customer service in the past.

The most significant include slow responses, especially when resolving unexpected scheduling problems. Experienced customer service representatives (CSRs) are thus essential for PCB manufacturers.

The challenges of improving customer service for these businesses also depend on their size. For example, small businesses typically require a rapid response from the CSR since they often submit multiple design changes before finalizing the product.

The challenge many manufacturers face when improving their customer service is accommodating the various sizes of businesses. For example, small businesses typically require a rapid response from the CSR since they often submit multiple design changes before finalizing the product. Furthermore, these clients also want assurances that a PCB manufacturer considers their needs as important as those of larger clients.

When selecting a PCB manufacturer, it is crucial to consider customer service from start to finish because this often determines a project’s success. A highly experienced partner can promptly report any problems with production and provide engineers who can continue to provide support from prototype to production.

In addition, partners with top customer service provide one-on-one support that allows you to develop your ideas into innovative products that will differentiate your company from its competitors.

Lastly, working with a leading PCB manufacturer will likely provide multiple communication channels like phone, email, and live chat. For manufacturers like Imagineering, combining technical expertise with client familiarity is key to driving the efficiency and convenience needed when ordering PCBs.

Integration of IoT and AI Technologies

Integrating the Internet of Things (IoT) and Artificial Intelligence (AI) into PCB technology is transforming this industry in 2023, providing greater efficiency and functionality through increased automation.

The IoT is a collection of devices that use sensors and processing capabilities to exchange data with other devices over a network. An IoT-based approach to telecommunication uses multiple layers of high-speed connectivity, especially for wireless networks.

- Mobile Devices (iPhones, Samsung phones)

- Smart Refrigerators (Samsung, LG)

- Smartwatches (Apple watches, Pixel watches)

- Medical Sensors (Blood pressure, EEG devices)

- Etc

However, PCBs for IoT devices must meet additional requirements on top of those for other PCBs. Nevertheless, manufacturers can still fabricate wireless PCBs more quickly because designers don’t need to worry about complex RF components due to their proven performance.

Many industries benefit from the IoT, especially healthcare, industrial automation, and wearable technology. Users often use this technology to control and monitor devices in the home and workplace remotely.

Here is a list of some of the industries that are benefitting from IoT:

- Healthcare Industries

- Industrial Automation Industries

- Wearable Technology Industries

- Manufacturing Industries

- Transportation and Logistics Industries

- Insurance Industries

- And more!

AI refers to software that can perform tasks commonly considered to require human intelligence, including converting text to speech and translating documents into other languages.

AI has grown for many years and expanded into virtually every industry. This trend will continue with PCB manufacturing due to the potential of AI for improving quality and production times.

For example, PCB manufacturers can use AI to collect data from multiple sensors. Machine learning (ML) software can then analyze this accumulated data and use it to improve fabrication efficiency and costs without compromising quality. In addition, AI has the potential to increase automation in PBC manufacturing.

This process has already been automated to some extent, but it has previously been challenging to ensure product quality without direct human interaction. All these advantages will likely ensure that AI technology continues to grow in PCB assembly.

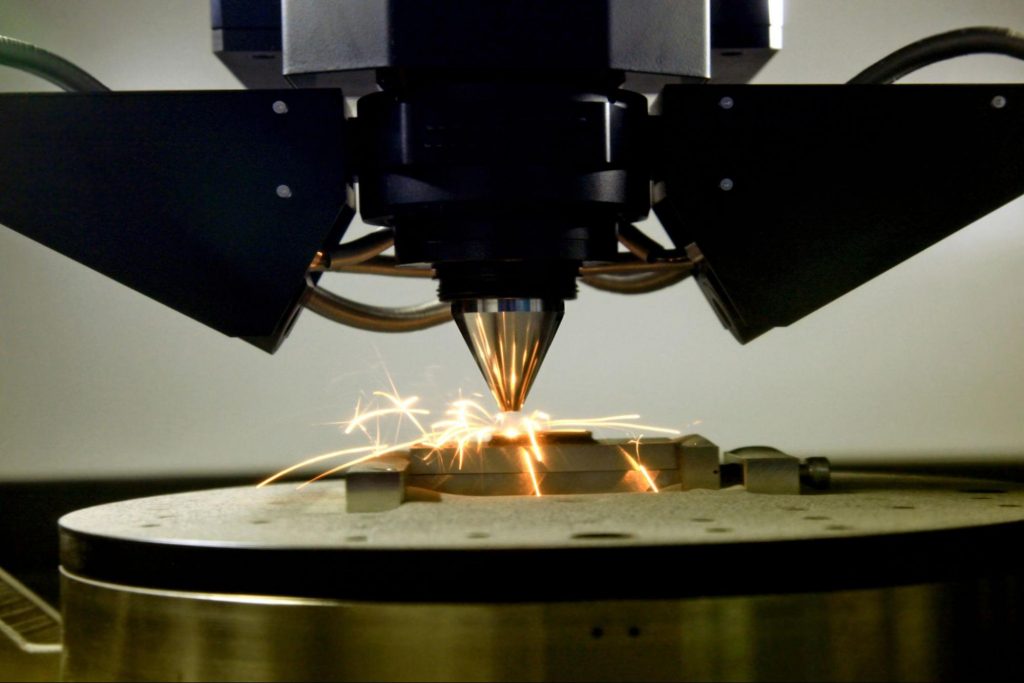

3D Printing of PCBs

3D printing is revolutionizing PCB design and manufacturing, which analysts expect to continue for the foreseeable future. This technique, called additive manufacturing, constructs a three-dimensional object from a digital 3D model typically created with computer-assisted design (CAD) software.

Manufacturers use 3D printing in various processes that involve depositing some material under the control of software. The most commonly used materials include liquids, plastics, and powder grains, typically added layer by layer.

3D printing is experiencing rapid growth in many industries, including PCB manufacturing. Its benefits in this industry include reduced costs, increased customization, and improved speed.

3D printing to make PCBs generally involves printing the substrate one layer at a time by adding liquid ink first, followed by the required surface-mounted components.

This technique for printing circuits on top of an existing shape is why 3D printing is so popular for PCB manufacturing. It allows the circuits to assume shapes that weren’t feasible with older techniques.

In addition, it reduces waste, making it more cost-effective and less harmful to the environment. 3D printing also becomes more beneficial as design complexity increases.

Innovative applications of 3D printing in PCB design and manufacturing include the co-deposition of multiple materials. This technique is critical for making PCBs with 3D printing because it has to print conductors and semiconducting materials simultaneously.

Researchers recently printed system-on-chip (SOC) microcontrollers with 7,000 times the memory of other flexible PCBs. Similar applications of 3D printing for PCBs will likely include environmental sensors and munitions inventory monitoring.

Commercially available systems can also use 3D printing to create diodes, LEDs, and thin-film transistors (TFTs) from organic polymers. Manufacturers can then scale these TFTs horizontally and vertically once they have the desired contact and gate configurations. The polymers are easy to dope and functionalize, allowing manufacturers to tune their electronic and optical properties according to the PCB’s requirements.

The potential challenges of 3D printing to create PCBs include material limitations and design constraints. For example, manufacturers need rigid semiconducting materials to optimize for different frequency bands.

Minimizing parasitic capacitance with various polymers makes 3D printing competitive with gallium nitride (GaN) to fabricate SoCs. These polymers are already used for building nonplanar PCBs, so applying them to semiconducting devices is a natural extension.

Reducing resolution is another challenge of using 3D printing for PCBs. The current limit for this technique is a width of one micron, but it would need to get down to the micron level to compete with the best available techniques. The most likely solution to this problem is to adopt a photolithography process or self-assembly for 3D printing.

The Importance of Working With a Trusted PCB Partner

The latest trends in PCBs include technological developments such as flexible substrates, AI, and 3D printing, but improvements in customer services are also changing PCB manufacturing.

The rapid evolution of this industry makes it important for engineers to stay up-to-date with emerging technologies and other ongoing changes related to PCBs. Design engineers and purchasing managers should consider these trends when selecting PCB manufacturers for their projects.

At Imagineering, we’re committed to providing our clients with the best possible service and support from design to production. Our team of experts is well-versed in the latest PCB trends and can help you find an innovative solution to any problems you have.

If you are ready to start, contact us today for a custom quote tailored to your specific needs.